Full-Service Supplier of Thermal Spray Coating, Laser Cladding, and Machining

Tough Coatings For Harsh Environments

We believe your Coating Vendor

Should Provide High Quality Coatings

Should provide high quality coatings

Button

Should Meet On-Time Delivery

Write your caption hereButton

Can Be Trusted With Your Valuable Components

Write your caption hereButton

Should Provide Experienced & Professional On-Site Technicians

Write your caption hereButton

Should Be Knowledgeable, Expedient and Proficient

Is knowledgeable, expedient and proficient

Button

Extreme Flexibility for

Extreme Projects

Your application is tough - and your market is even tougher. Rugged, harsh service environments demand optimal performance from all machinery and parts. At Hayden Corporation, we believe that your parts should survive the most extreme environments.

Thermal Spray Coating & Laser Cladding

Our expert team of craftsmen and technicians know the best solutions to the greatest abrasion, adhesion, corrosion, heat, and other wear problems affecting your parts.

-

LASER CLADDING

→We've got the knowledge you need.

-

THERMAL SPRAY

Learn more →We've got the knowledge you need.

-

HARDFACE WELDING

Learn more →We've got the knowledge you need.

-

SPRAY & FUSE COATING

Button -

ONSITE SERVICES

Button

MACHINING & LABORATORY SERVICES

ButtonTrusted Thermal Spray Coaters for Over 100 Years

For over 100 years Hayden Corporation has been the industry leader in high-performance thermal spray and laser cladding. Watch our quick company overview video to learn why companies choose us.

Top Industries We Serve

Our thermal spray and laser cladding expertise spans across numerous industries

-

Aerospace

Learn More -

Fluid Handling

Learn More -

Industrial Equipment / Components

Learn More -

Military / Defense

Learn More -

Oil & Gas / Mining

Learn More -

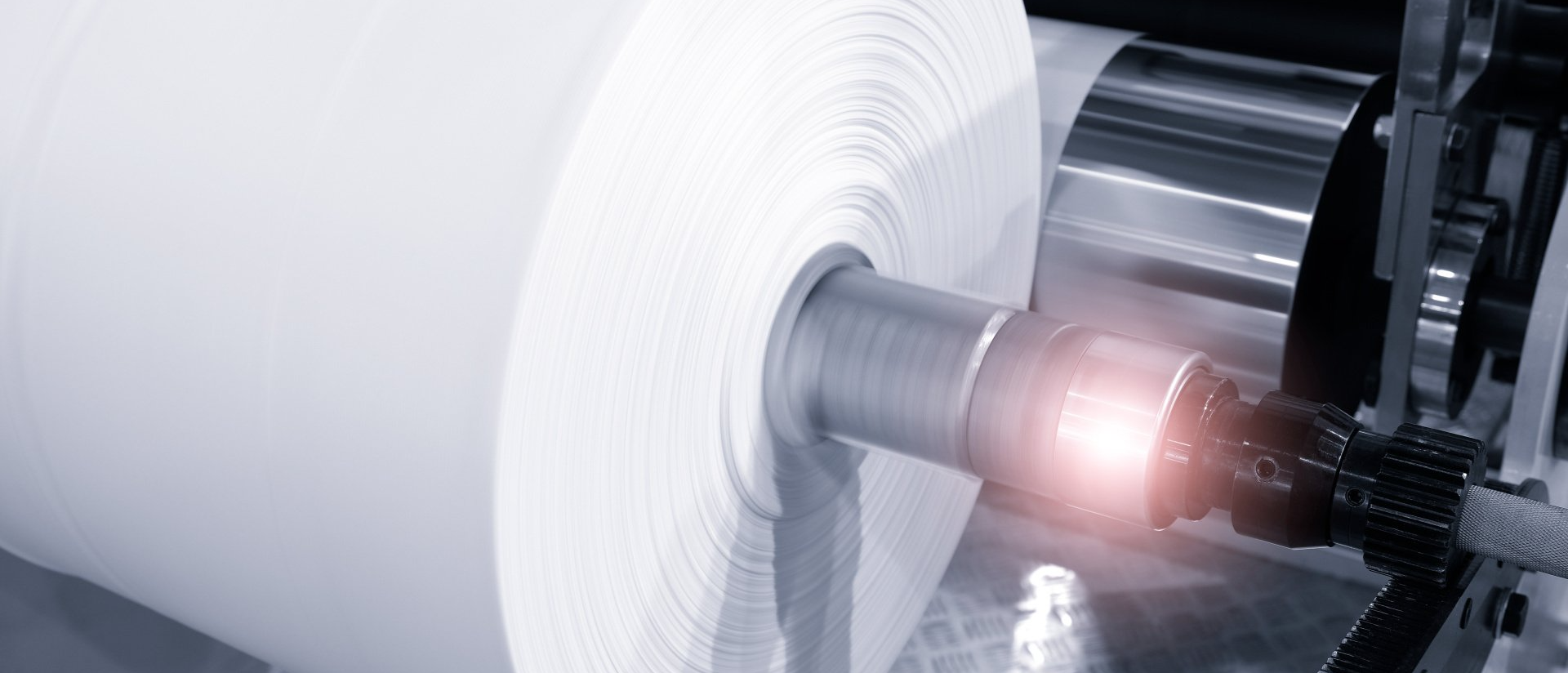

Plastics / Recycling

Learn More -

Power Generation

Learn More -

Pulp, Paper & Converting

Learn More

News & Resources

We are dedicated to our partners and we believe that the more informed you are, the better decisions you will make.

Read our latest resources and new articles.

Contact Hayden Corp.

Have a question or have a specific need? Contact our main office or send us a message online.

Contact Us Home Page

We will get back to you as soon as possible

Please try again later

Tough Coatings for Harsh Environments

The Northeast's only full-service supplier of thermal spray coating, hardface welding, and machining. Your application is tough - and your market is even tougher. Our solutions-based expert team of craftsmen and technicians know the best solutions that affect your parts.

MENU