Full-Service Supplier of Thermal Spray Coating, Laser Cladding, and Machining

Flame Spray Coating & Arc Wire Spray

Sprayed Coatings ▿

Flame Spray and Arc Wire Specialists

Hayden Corporation is a leading provider of Flame Spray coatings and Arc Wire Spray services. We have over 100 years of industry experience, and our highly skilled professionals know the best solutions for your parts. Flame spray and arc wire are perfect for many applications, including metal coatings on metals, plastics, and composites. Our arc wire spray process is ideal for large on-site projects and can provide a durable, long-lasting finish. Whether you need a single component coated or an entire production line, we have the experience and expertise to make sure your parts are protected against the most extreme environments.

Flame Spray Coating

Flame spray coatings are a surface enhancement that can be applied quickly and easily to many types of components. The process involves using a oxy-acetylene flame to spray metallic or composite coatings onto surfaces. This coating can provide enhanced traction, improved thermal conductivity, cathodic protection, and other

improvements. Flame spray coatings are typically used in industrial and commercial applications but can also be used for general repair and maintenance tasks. One of the key advantages of flame spray coatings is the portability of the equipment. Flame spray coatings can easily be applied on-site for applications that are too large or costly to ship.

Common Applications

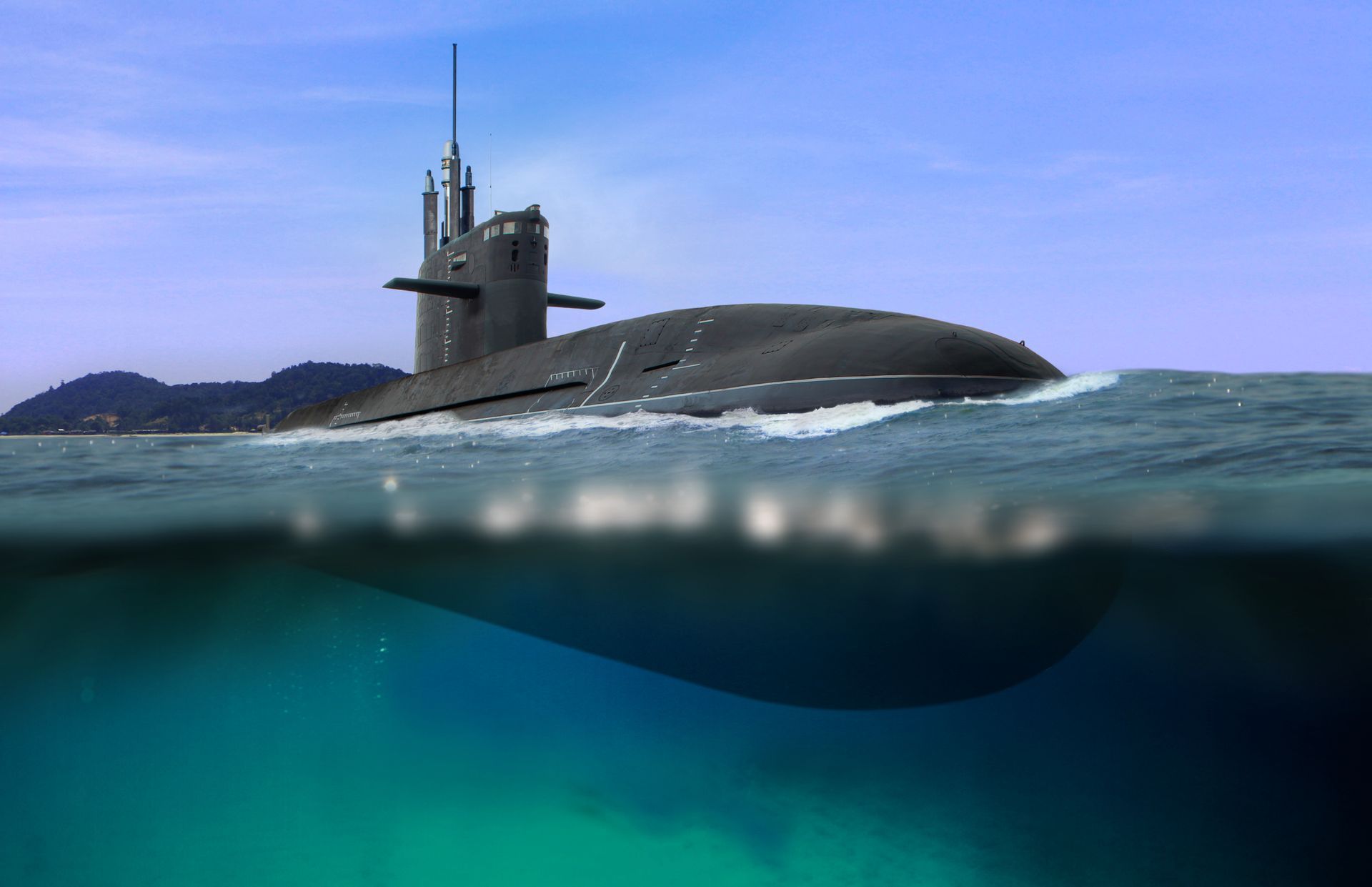

Corrosion Protection & Corrosion Resistance

Flame spraying can provide an effective barrier against atmospheric corrosion. The coating can act as a barrier between corrosion-prone steel and the environment, substantially reducing the rate of oxidation and increasing the lifetime of outdoor or marine equipment by several multiples. This type of coating provides galvanic protection and is often used in marine and offshore applications but can also be used on land-based structures.

Small Part and Spot Coating

Flame spray coatings are ideal for small parts and spot coating individual components. The process is quick and easy, and is often the best choice for repairs and recovery of machining defects..

Thermal Conductivity Enhancement

Flame spraying can improve the thermal conductivity of metals. This is achieved by increasing the surface area of the metal, which allows heat to dissipate more quickly. The enhanced thermal conductivity can be used to improve the efficiency of heat-sensitive equipment and improve the overall performance of the equipment.

Wear Surface Buildup and Repair

Flame spraying can be used to repair damage caused by wear, corrosion, or oxidation. It can also be used to restore worn surfaces and improve the performance of components in high-wear applications. This type of thermal spray coating is often used in heavy-duty industrial applications where wear and tear are common.

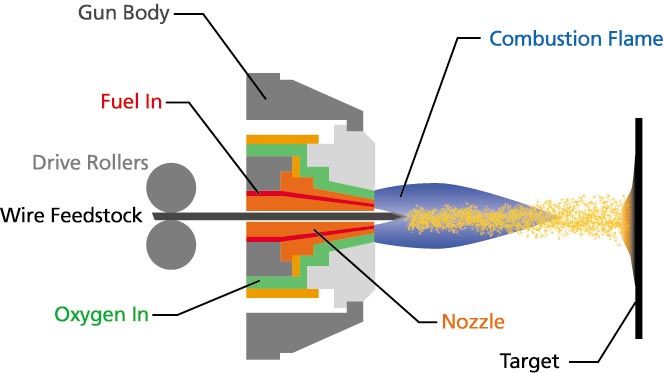

Flame Spray Method

Flame spraying actually describes two similar but different methods: flame spraying of wire and flame spraying of metal powder. All flame spray guns, however, perform the same essential function of heating and projecting the coating material through the use of an oxy-fuel flame and a pressurized carrier gas jet.

Materials sprayed with this process come in both wire (flame wire process) and powder (flame powder process) forms, depending on the gun used. In either case, the gun serves to melt and atomize or soften the material as it is fed into the flame, and eject the soft or molten particulate in a directed stream through the gun’s nozzle.

Flame Spray Practice

Flame spray guns typically require very little additional equipment. Most powder-fed guns have a hopper built into the gun body. Others use a small external powder feed unit. Wire guns usually have a mechanism built into the gun body to guide the feeding of wire and regulate its speed. Typically, only supply lines for oxygen, fuel, and, occasionally, compressed air are required. Beyond the obvious ease of transport and installation this feature affords, this simplicity also significantly reduces setup time and the margin for operator error.

The relatively low particle velocity of the flame spray process leaves a coating of moderate but not outstanding density. As a result, flame sprayed coatings of self-fluxing alloys are often candidates for spray and fuse processes where the additional fusing stage can allow the coating to flow more freely and fill many of the voids that the spray process may have left.

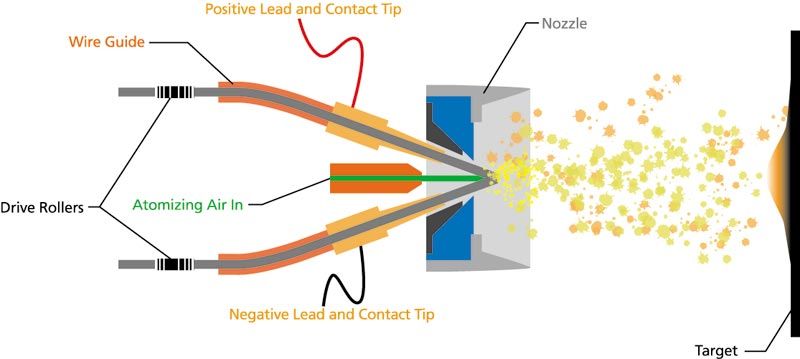

Arc Wire

Arc wire (also referred to as twin wire arc spray) brings the operational simplicity and portability of MIG welding technology to the field of thermal spray. The result is a system capable of applying a quality surface treatment at virtually any location. The arc spray process begins by feeding two consumable electrode wires into the spray gun. The electrically charged wires are brought together at the gun nozzle where they form an arc that melts the wire. The molten droplets are then arc-sprayed onto the substrate, providing a coating that is resistant to wear and corrosion. Arc wire systems are significantly less expensive than traditional thermal spray systems, making them an attractive option for many applications. Whether you need to coat a small part or a large structure, arc wire thermal spraying provides a versatile and cost-effective solution.

Additionally, the high feedstock capacity of arc wire systems makes them ideal for coating large areas, such as structural surfaces and large rolls.

Arc Wire Spray Common Applications Include:

Journal and Bearing Repair and Buildup

Arc wire thermal spray coatings can be used to repair and rebuild worn or damaged journals and bearing areas. The coating helps to protect the journal from further wear and also provides a smooth surface for the bearing to rotate on.

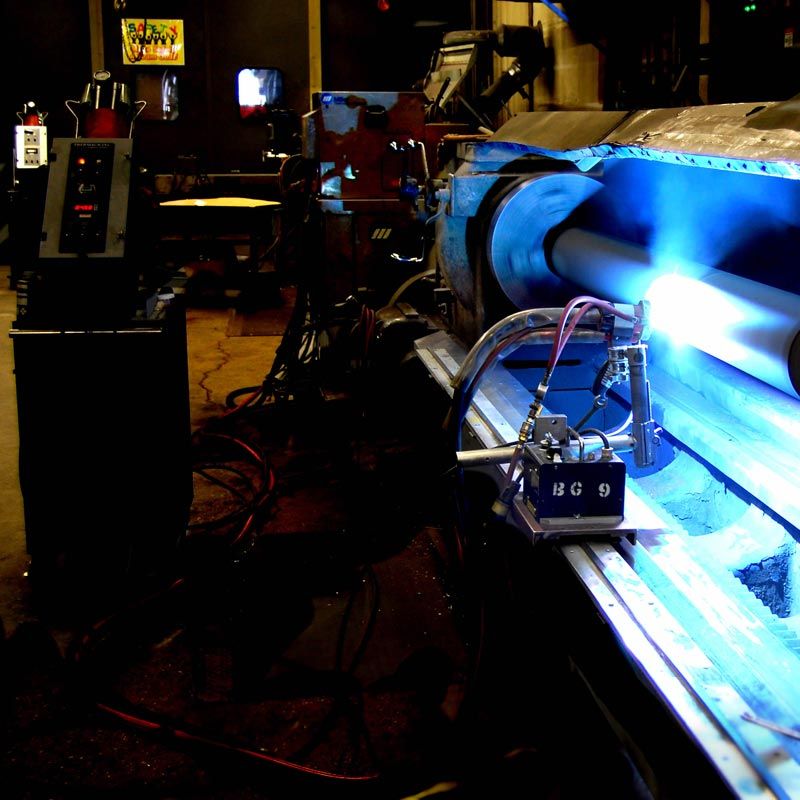

Roll Resurfacing

Rolls are a vital part of many industrial processes and often suffer wear and tear over time. This can eventually lead to damage, which impacts the quality of the products being produced. In some extreme cases, it may even be necessary to replace rolls entirely. However, arc wire thermal spraying can provide an alternative to replacing damaged rolls. This process involves coating the roll with a layer of metal using arc spraying, and then machining or grinding the newly applied material to required dimension and finish. Hard coatings can help protect the roll from further wear and tear and restore its surface to a like-new condition. Arc wire thermal spraying is an affordable and effective way to extend the life of rolls, and it can help to keep production lines running smoothly.

Exposed Outdoor Structure Protection

Exposed outdoor structures are susceptible to a variety of weather-related damage, including corrosion. Arc wire thermal spray coatings of aluminum and zinc can help to protect these structures from the elements by providing a cathodic barrier against moisture and other corrosive agents.

Arc Wire Spray Method

Arc wire thermal sprayed coatings bear a similarity to flame wire coatings in that both are applied by completely melting and atomizing a wire feedstock before projecting the droplets onto the work surface. Rather than using an oxy-fuel flame to liquefy the metal, an arc wire system uses the heat of an electric arc. In a twin wire system, this arc is struck at the merging tips of two oppositely charged wires made of the material to be sprayed. The point of intersection of these wires is positioned directly in front of a jet of compressed air. As the heat from the arc melts the wire, the jet blows molten droplets forward onto the part. A mechanical feed mechanism pushes both wires forward to maintain the arc and the flow of material.

Arc Wire Spray Practice

The compressed air jet used in the arc wire system tends to promote oxidization of the molten particulate more readily than other systems using inert carrier gasses. As a result, photomicrographs of arc wire-sprayed coatings tend to reveal a higher percentage of oxidized material than those of coatings applied by plasma or HVOF systems. The added oxide content also increases the hardness of these coatings over those of other processes. Though this oxidation may be a concern in some applications, the high mechanical interlock of particles in an arc wire coating often makes this chemical feature irrelevant. Alternatively, nitrogen may be used as an atomizing gas to minimize oxide formation in the deposit.

Arc spray coatings also afford the unique opportunity to create custom 50-50 pseudo-alloy coatings. The arc must be struck between two wires, but the wires need not necessarily be of the same material. By using two wires of differing metals, the coating applied will be a blend of these. Though this feature is seldom requested, it is only possible through the use of an arc wire system.

Thermal Spray Coating Experts

Since 1919, Hayden Corp has remained the industry leader in

Thermal Spray Coatings

and

Laser Cladding

Technologies. Our experience and expertise in the thermal spray industry are unmatched. Contact us today to learn more about our services or to request a quote. Call our office at

(413) 734-4981

or

contact us online.

Flame Spray & Arc Wire

News & Resources

Online Quote Request

Complete our online quote request form below.

We will contact you within the same business day.

Flame Spray & Arc Wire Quote

We will get back to you as soon as possible.

Please try again later.

Contact Hayden Corp.

Have a question or have a specific need? Contact our main office or send us a message online.

Tough Coatings for Harsh Environments

The Northeast's only full-service supplier of thermal spray coating, hardface welding, and machining. Your application is tough - and your market is even tougher. Our solutions-based expert team of craftsmen and technicians know the best solutions that affect your parts.

MENU