Full-Service Supplier of Thermal Spray Coating, Laser Cladding, and Machining

Laser Cladding for Restoration

Laser Cladding for Restoration

Low heat input and precise control of material deposition make laser cladding a perfect tool for making the old new again.

The combination of low heat input, heard-wearing materials and unbreakable metallic bonding make laser cladding an ideal tool for repairing or rebuilding surfaces that have lost their size or shape to the ravages of time. Bring your worn or damaged part to us, and we’ll bring it back to life.

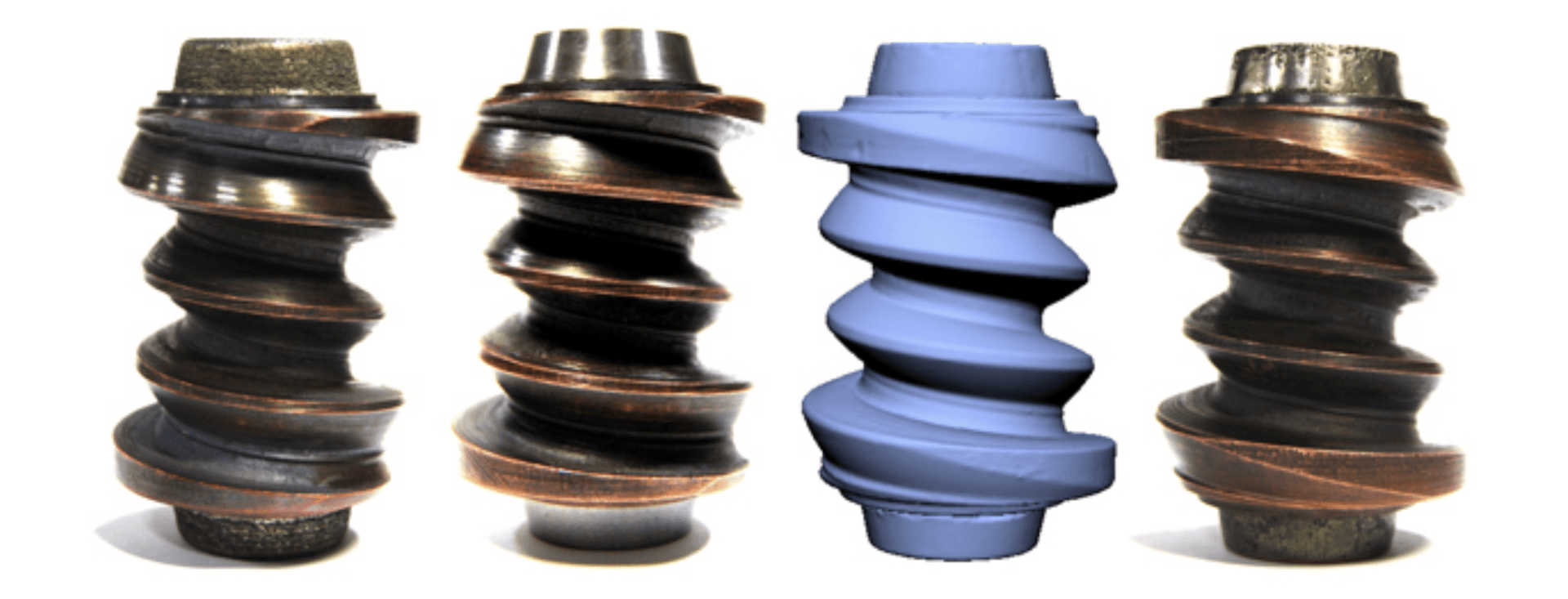

A collector of antique tractors had a problem: the bearing fits on the steering worm of his 1945 John Deere Model L tractor were badly pitted and worn. While new tapered bearings and cages could be bought off the shelf, the Gemmer worm was no longer available, and the machines that made them ended up in factories in other parts of the world. The collector came to Hayden to see if we could help.

The piece was small, and the amount of material required was minimal, so we decided to take the job on. Fortunately, the gentleman had a similar piece on loan that we could use as a reference for establishing dimensions. We elected to rebuild the area with a hard-wearing steel alloy that would be tough enough to withstand the bearing action but soft enough to avoid risk of cracking.

The complex combination of the worm’s helical gear path, combined with the hourglass shape traced by the pivoting sector cam would make this piece difficult to draft, but a quick three-dimensional scan of the worm produced an accurate solid model that could be used for programming the laser cladding process. To keep heat input minimal, we chose to use a small diameter spot size, and place several thin weld beads close together, rather than apply the material quickly. Contours were programmed to build up the worn tapers by approximately 0.040″ per side, in order to allow enough material to re-establish the correct diameter by grinding, afterward.

The piece was mounted onto an arbor and placed into the rotary position of the laser system. Once the piece was loaded, the processing program could be aligned with the actual part, and a test could be run to ensure proper alignment. Since the program was created in the virtual programming suite based on an accurate three dimensional model of the part, the program fell right into line, tracing the tapers perfectly. Due to the laser’s tight control and minimal heat input, the worm never exceeded 180 degrees Fahrenheit, and the hardened gear body was never at risk of loosing its physical properties.

Once the cladding was complete, the piece moved to the grind shop, where our machinist set the 15-degree taper, cleaned the adjacent face and ground the diameters on both ends to match the sample piece we had on loan. The grind operation restored the surface finish and size required to match the bearings, and the entire assembly could be re-packed and installed to run like new.

Hayden Laser Services, LLC has performed similar repairs to restore original sector shafts for classic Pierce Arrow automobiles, and other irreplaceable components.

Visit our

laser cladding page to learn more.

Contact us to receive a

free quote

Questions?

Our staff is always available to answer your questions.

Categories

Tough Coatings for Harsh Environments

The Northeast's only full-service supplier of thermal spray coating, hardface welding, and machining. Your application is tough - and your market is even tougher. Our solutions-based expert team of craftsmen and technicians know the best solutions that affect your parts.

MENU