Full-Service Supplier of Thermal Spray Coating, Laser Cladding, and Machining

Spray & Fuse Thermal Spray Coatings

Sprayed Coatings ▿

Spray & Fuse Coating Services

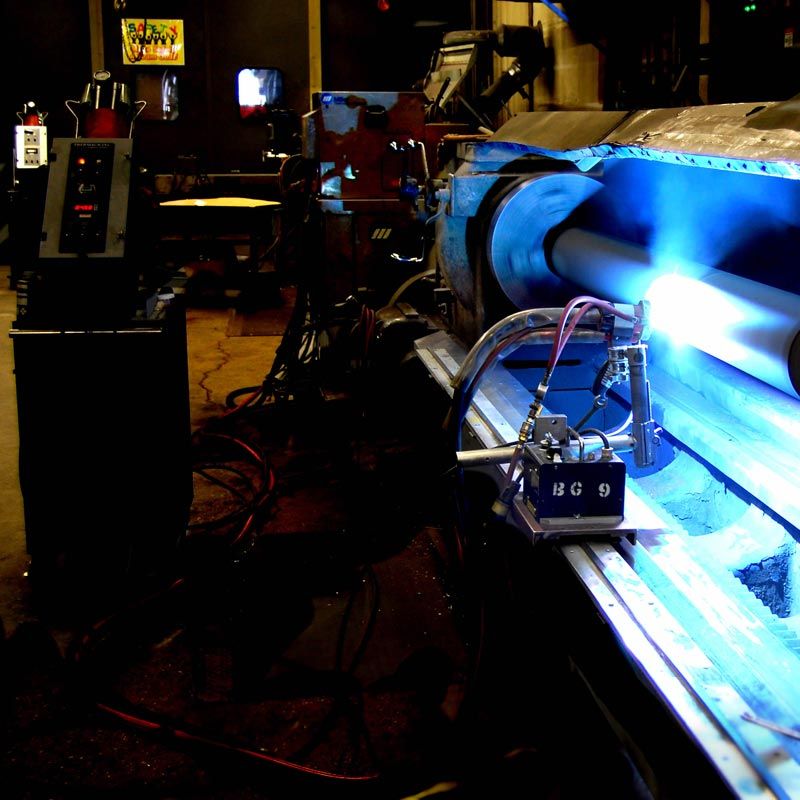

The spray and fuse coatings have been metallurgically developed to perform at their peak after having undergone an intense fusing stage. This line of coatings combines the ease of application of a thermal sprayed coating with the tough, high-stress wear characteristics of a hardface weld overlay.

Although we consider these to be some of the highest-performing coatings Hayden has to offer, the method of application demands careful consideration before specifying a spray and fuse coating. Our engineers can help you determine if this procedure is right for your application. High temperature process to be engineering in advance to for alloyed bond characteristics.

Spray & Fuse Capabilities

Low Coating Profile

Spray and fuse coatings allow the use of high-performance alloys typically only found in cast or hardfaced components at comparatively lesser thicknesses. As only the wear surface typically requires the protection these materials afford, substantial savings can be found in fabricating a component from a lesser-grade material and then applying a Hayden spray and fuse coating to the critical wear surfaces. Tight tolerances allowed by spray and fuse coatings can be especially helpful in mechanically precise applications, such as pumps and granulators.

- Improved Resistance to Gouging Wear

The fusing process literally bonds coating particles to each other, much as a welded material is bonded to a substrate. The result is a coating virtually free from the inter-particle spaces, or voids, and oxides that can cause a poorly applied thermal sprayed coating to fail when subjected to shearing or gouging wear.

High Coating Purity and Integrity

Fused coatings exhibit levels of intermolecular bonding comparable to a welded material, but, due to the carefully controlled application of material and heat, the applied coating experiences little chemical dilution, if any, from the substrate. The coating interface exhibits characteristics similar to a brazed union.

Spray & Fuse Coating Application Criteria

The fusing process introduces high heat levels into the part, similar to, or in excess of, welding temperatures (around 1,900- 2,050°F). Work to be coated must be capable of withstanding high levels of heat without risk of deformation.

As with any process where two metals are bonded structurally, issues of metallurgical compatibility must be taken into consideration.

Some materials will not interface well with others. Further, coefficients of expansion of the substrate and coating must be similar to avoid cracking and warping as the part cools.

Spray and fuse coatings may not be applied to nonmetallic base materials.

Spray and Fuse Resources

Spray & Fuse Coating Quote Request

Complete our online quote request form below.

We will contact you within the same business day.

Spray and Fuse Quote Request

We will get back to you as soon as possible.

Please try again later.

Contact Hayden Corp.

Have a question or have a specific need? Contact our main office or send us a message online.

Tough Coatings for Harsh Environments

The Northeast's only full-service supplier of thermal spray coating, hardface welding, and machining. Your application is tough - and your market is even tougher. Our solutions-based expert team of craftsmen and technicians know the best solutions that affect your parts.

MENU