Full-Service Supplier of Thermal Spray Coating, Laser Cladding, and Machining

About Hayden Corporation

Quality and Flexible Thermal Spray Coating Services based in Massachusetts

4 Generations and Over 100 Years of Trust

Our Focus is on quality and flexibility

Hayden Wire Works opened its doors in 1919 under the entrepreneurial vision of Charles E. Hayden, servicing New England’s many paper mills. Today, under the leadership of Daniel Hayden, the company is an active thought leader in its field and continues to expand its thermal spray, laser cladding and field services to new industries, applications and customer partners across North America.

Our Beliefs

We believe that your parts should survive the most extreme service environments

You design and develop parts that must endure harsh, severe service applications. Through specialized talent and processes, Hayden Corporation assures your parts can achieve the durability needed for optimal performance. Our expert craftsmen and technicians can solve your most challenging specifications and requirements.

We believe your parts should achieve both their targeted lifespan and targeted functionality

The Hayden Corporation team is built on materials expertise. The application of tough thermal spray coatings and laser-clad overlays is not taught to engineers in their formal education and training. Engineers turn to us as the authority on protective coating and overlay materials. Our staff is knowledgeable in materials, and we offer many material options for thermal spraying and laser cladding. We help you choose the right materials for the right application.

We believe that your delivery date should not be driven by supply chain availability.

Efficiency is a crucial tenet of our work. We take pride in covering more stages of the supply chain than the competition, while also delivering parts back to our customers faster. We support our efficiency goals with in-house processes and strategic partnerships for single management of all R&D, milling, coating and finishing work.

We believe your outage or machine downtime must be minimized, no matter how big or small.

We understand that some of your machine repair needs must be met on-site. We support your outage needs with on-road technicians, unique mobile equipment and low-heat processes that will keep all components of your machinery intact. Power plants, paper mills, and other high-demand industries trust Hayden Corporation to meet their outage repair needs expediently and proficiently.

A History That Extends Over 100 Years

The Hayden Wire Works opened its doors in 1919 under the entrepreneurial vision of Charles E. Hayden, an installer of wire cloth for the Springfield, MA, firm Cheney Bigelow. Hayden endeavored to bring an unprecedented level of service to the score of paper mills lining New England’s rivers and canals. Charles had learned the trade of paper-making from the inside out as a field serviceman for Cheney Bigelow. His work brought him into the mills themselves, giving him an inside view of the specific needs of the paper industry. What he discovered was a demand for a higher level of service and support for the maintenance of the massive paper machines that operated day and night to keep these mills, and the communities that depended on them, going.

Working from his trade experience, Charles developed a firm devoted to providing high-quality wire cloth for cylinder molds (the large drums that first lift the sheet of paper pulp out of the stock chests and into the network of rollers) and, more importantly, a team of highly skilled field service technicians who could not only install and service the cloth but the entire mold. From its facility centrally located in West Springfield, MA, neighboring “Paper City,” Holyoke, MA, Hayden Wire Works wove and installed cloth for mills across the Northeast. Throughout its early years, the Wire Works operated two looms at the facility and supported a small network of service technicians.

Although the firm was not the largest supplier of wire cloth by any means, Hayden’s success came from its careful attention to the needs of its customers and their industry as a whole, a trademark feature that continues to define our company today. As a result, the sale of wire cloth as a raw product remained secondary to the services Hayden offered in tandem with the product line. Installation, re-covering, and repair of damaged molds brought a steady flow of work into the shop, and attention soon turned to servicing and rebuilding damaged or worn molds using methods that might extend their operational life.

Charles Wesley (“Wes”) Hayden continued Hayden’s efforts to improve the performance and specifically the wear-resistance of cylinder molds, and then expanded the reach of this service to include other essential paper machine components. Applying the knowledge of wear patterns gained through rebuilding countless cylinders, he also developed a new product line for Hayden Wire Works. Not only would Hayden manufacture the cloth covering for the cylinders, but they’d construct an entire mold using specially cast, Hayden-designed components. Experience had shown them the weaknesses of typical molds, and each weakness was addressed in the Hayden design. Traditional filigreed spiders were replaced with sturdier cast ribs, each bearing the Hayden name. The molds were assembled and covered on site, and the size of the operation and the volume it produced demanded the first of several expansions to the company’s building on Sylvan Street.

The fabrication business also signaled the first definite step beyond the wire cloth business for the company. Wes would eventually take the company out of the wire cloth business altogether and set it exclusively in the field of wear protection and repair, where it continues today, but there were several stops along the way. Wes Hayden was an innovator and, like his father, an avid entrepreneur. One of his most notable contributions to the industry was a patented process for seamlessly welding stainless steel wire cloth using corrosion-resistant precious metals. Before this process had been developed, stainless wire cloth, such as that used in our cylinder molds, had to be stretched and stitched like fabric, making roll covering a time-consuming and difficult process. Now durable stainless cloth could be applied as quickly and easily as softer, less durable bronze cloth.

Developments within the wire cloth industry were only one of his interests. Just as Charles had, Wes stayed current with the special needs of the paper industry by remaining actively involved in it. Wherever a field call would take him, Wes kept an eye open for an opportunity to expand the range of Hayden’s services. Under his supervision, Hayden offered several services to the paper-making and allied industries, ranging from a trademarked line of Kab-O-Rap fiberglass bulk fluid storage tanks to a process for building up worn areas of machine components with a gun that sprayed metal. Fiberglass tanks eventually left our product line, but the other service, a process called “metallizing,” seemed to do better than just carry its own weight.

By their nature, paper mills are filled with heavy rotating machinery. From calendering rolls and their bearings and drives, to the massive pumps that circulate water and pulp throughout the process, mills were constantly battling the inevitable wear that develops as a spinning part operates. Metallizing offered a fast, easy and cost-effective alternative to exchanging worn parts for new. Furthermore, the material used to build up a worn surface didn’t necessarily need to be the same as that it was replacing. Superior, more durable metals or ceramics could be applied that could last several times longer under the same stress.

The metallizing process essentially consists of projecting particles of metal that have been heat-softened onto a roughened surface. As the soft particles impact, they deform, pressing into the contours of the surface they strike. The process looks a great deal like spray painting, but, unlike paint droplets, the metal “splats“ do not chemically bond with the other particles already deposited. As they impact, they simply press into and mechanically lock around the rough surfaces of the particles beneath. The result is a tough layer that can be ground and finished just like the material it is replacing. The journal and bearing surfaces of dryer rolls such as these were ready candidates for metallizing, as the cost of a few thousandths of an inch of metal was significantly less than the cost of a new roll.

The corrosive environment in and around high-volume pumps made metallizing an ideal solution for repairing frequently worn parts, such as impellers and plungers. In fact, the range of components that could benefit from metallized coatings was so great that Hayden soon devoted nearly all of its resources to supporting this service. In time, even wire cloth was phased out of production, and Hayden became a service firm exclusively.

The Hayden team, circa 1960, was composed primarily of field servicemen and in-house machinists. Eventually, with the development of the thermal spray process, trained spray technicians also became a regular part of the shop staff. In essence, the composition of the staff as it remains today has its roots in this phase of Hayden’s growth.

The success of Hayden’s wear-resistant applications eventually brought contracts from outside the mills, more specifically, from the OEMs who were supplying equipment to the mills, and Hayden was soon applying coatings to nearly any wear component that came through its doors.

Here, a corrosion-resistant protective release coating is being flame sprayed onto the interior of a mold used to cast fiberglass boat hulls. Pump components were among the first high-volume OEM components to regularly utilize Hayden’s protective and wear-resistant coatings. Hayden was an early applicator of high-performance spray-and-fuse style coatings. These coatings require a level of craftsmanly technique in their application that only comes with experience. By growing with this process since its beginnings, Hayden’s technicians benefit from a tradition of craftsmanship not commonly available in this industry.

Hayden’s interest in new applications and practices has kept the company at the forefront of wear technology. We have actively worked with equipment manufacturers and developers to refine new processes and methods for wear and corrosion resistance. Hayden was one of the first firms to offer hardface weld overlays in tandem with thermal sprayed coatings. We were among the first to develop a process for plasma coating “Moyno” pump screws. And Hayden was the first firm to apply thermal sprayed coatings to massive Yankee dryer rolls.

Under the leadership of John Hayden, grandson of Charles E. Hayden, the company grew at an unprecedented rate as we pursued new industries and applications for the thermal spray process. With the papermaking industry in decline in the Northeast, John aggressively sought new markets for the technology, educating engineers and designers about the uses and strengths of thermal spray coating systems. The result was the migration from one-off coating applications to the integration of coatings as value added enhancements for new equipment. Coating systems provided by Hayden Corporation became part of customer specifications, and the first consistent, high-volume coating work began to flow through the shop. In the early 1980s Hayden finally outgrew its facility on Sylvan Street and moved a few hundred yards away into its current home at

333 River Street. What was, at the time, a seemingly cavernous plant, compared to our Sylvan Street shop, has even now come to feel a bit cramped at times. John’s initiative and very active involvement in several trade organizations has broadened the range of businesses we serve to include everything from automotive to plastics, and, in the 35 years of his leadership annual sales has grown by more than ten times.

Trade Affiliations

Hayden Corporation takes an active part in several organizations associated with our customers’ industries as well as our own by contributing our developments and findings to trade journals and participating in online discussions, conferences, and industry forums.

By actively involving ourselves in these organizations, Hayden is able to keep abreast of the latest technologies and discoveries in the field of thermal sprayed coatings, and to learn more about the developments that are shaping the ways we can best serve the industries we support.

These organizations have been at the forefront of their respective growing fields, and are yet another excellent resource that allows Hayden to provide the best possible service.

We appreciate their support and encourage our clients to support them as well. Below are links to a few of these organizations. We encourage you to take a look at their sites and familiarize yourself with their services.

-

City skyline

International Thermal Spray AssociationInternational Thermal Spray Association

-

Birthday Sparks

ButtonThe American Welding Society

-

Fashion Magazine

ButtonThe National Tooling and Machining Association

-

Blurred Lines

ButtonThe American Society for Metals, International

-

Button

Associated Industries of Massachusetts

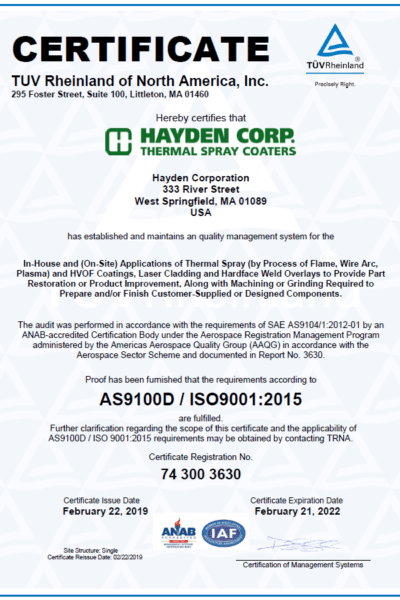

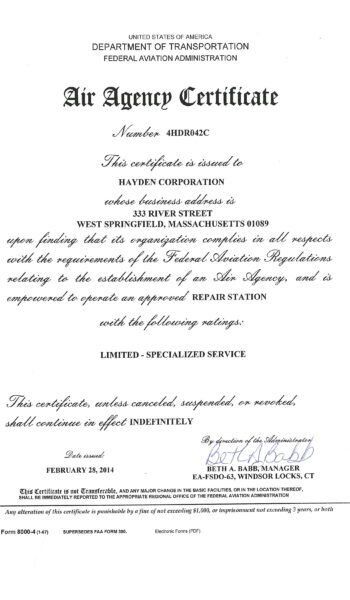

Quality Certifications

Online Quote Request

Complete our online quote request form below.

We will contact you within the same business day.

About Us

We will get back to you as soon as possible.

Please try again later.

Contact Hayden Corp.

Have a question or have a specific need? Contact our main office or send us a message online.

Tough Coatings for Harsh Environments

The Northeast's only full-service supplier of thermal spray coating, hardface welding, and machining. Your application is tough - and your market is even tougher. Our solutions-based expert team of craftsmen and technicians know the best solutions that affect your parts.

MENU