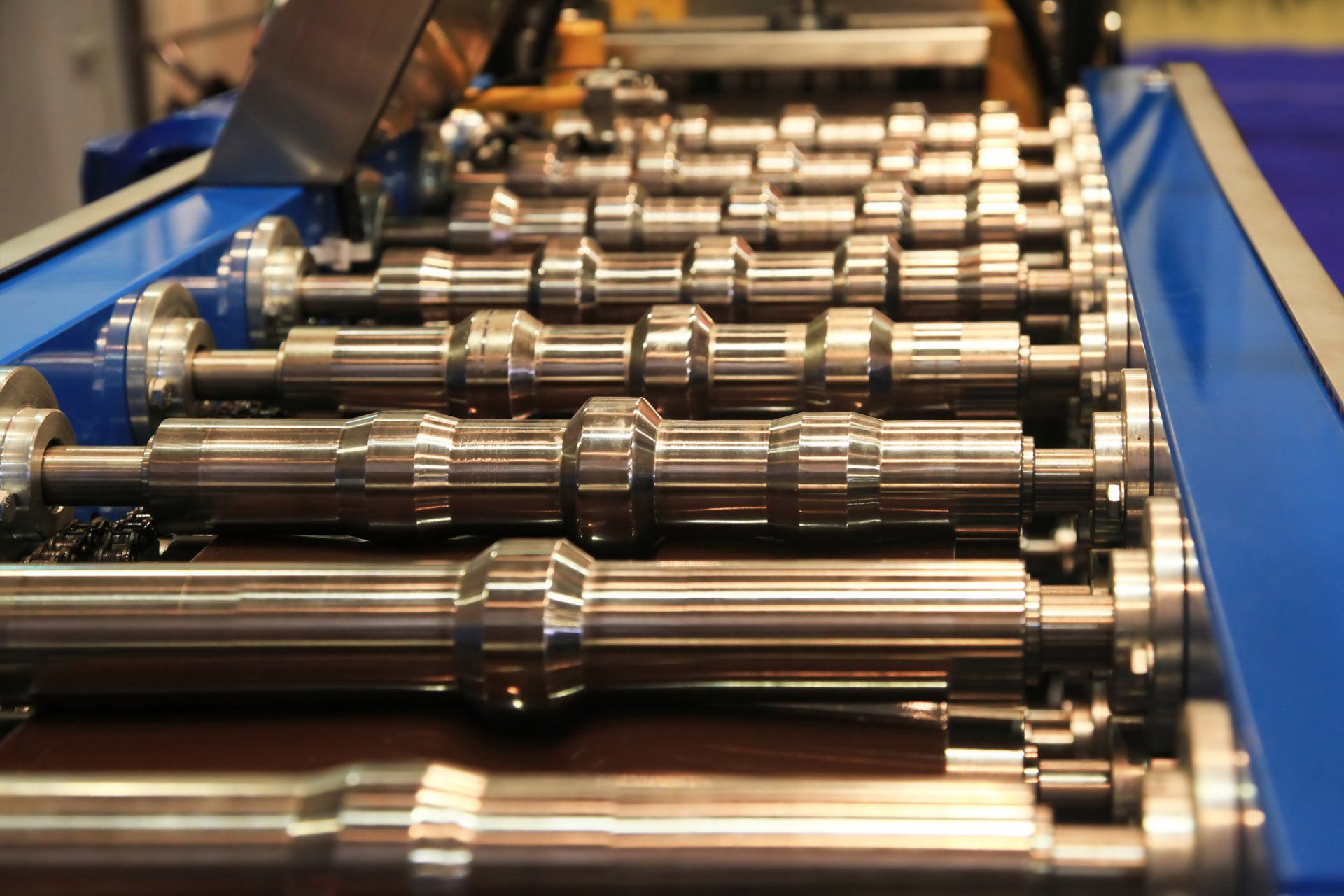

Printing and Paper Manufacturing - Benefits of Thermal Spray Traction and Anti-Skid Surface Coatings

In the printing and paper manufacturing industries, a high degree of precision is essential. Uneven surfaces can cause paper to slip and tear or impede the function of moving parts. A thermal spray anti-skid surface coating can alleviate these issues by providing a textured, durable surface that helps grip materials and maintain uniform sheet tension and smooth movement. Thermal spray coatings are applied using specialized equipment that heats the coating material to a high temperature before spraying it onto the surface, where it quickly cools and solidifies. The resulting coating is extremely hard and wear-resistant, making it ideal for applications where a high level of friction is needed. In addition, the textured surface of the coating helps to prevent slippage, ensuring that materials move smoothly through the manufacturing process. By investing in a thermal spray anti-skid surface coating, businesses in the printing and paper manufacturing industries can improve the consistency and quality of their products.

4 Main Benefits of Anti-Skid Traction Coatings

There are many benefits to using thermal spray anti-skid coatings, including:

Improve The Grip of Rollers and Other Machinery:

In the printing and paper industry, smooth and even movement is essential to avoiding jams and other disruptions in the manufacturing process. By improving the grip of rollers and other machinery, anti-skid coatings can help keep materials moving smoothly.

Reduce Downtime:

Uneven surfaces can cause friction that leads to wear and tear on machinery. This can eventually lead to breakdowns and other mechanical problems in the manufacturing process. By using an anti-skid coating, businesses can reduce downtime by ensuring that their machinery runs efficiently and reliably.

Improve Product Quality:

Product quality is of the utmost importance in the printing and paper manufacturing industry. Any deviation in machinery can result in an imperfect final product. Anti-slip coatings ensure that the printing process is smooth and uninterrupted, resulting in a higher-quality product.

Extend Life of Equipment:

In addition to reducing downtime, thermal spray anti-skid coatings can also extend the life of equipment by protecting it from wear and tear. This can save businesses money in the long run by reducing the need for frequent repairs or replacements.

Methods Used to Achieve Anti-Slip Surface Coatings

There are several methods that can be used to achieve an anti-skid surface coating, including:

Plasma Spray

Plasma spray is a thermal spray process that uses a high temperature plasma jet to heat and propel coating material onto a surface. Plasma thermal spray coatings are effective for friction, wear, and dielectric applications such as corona treater rolls.

Arc Wire Spray

Arc wire spray is a thermal spray process that uses an electric arc to melt and propel wire coating material onto a surface. Arc wire is efficient and ideal when covering a large surface area. It is also capable of creating very rough, high-traction finishes.

Flame Spray

Flame spray uses an oxy-actylene flame to heat and propel coating material onto a surface. This method is often used for small, delicate surfaces and is especially suitable for on-site application.

Improve The Quality and Efficiency of Your Manufacturing Process

Thermal spray traction coatings provide several benefits for businesses in the printing and paper manufacturing industry. These coatings improve the grip of rollers and other machinery, reduce downtime, improve product quality, and extend the life of the equipment. There are several methods that can be used to achieve an anti-skid surface coating, including plasma spray, arc wire spray, and flame spray. By investing in a thermal spray anti-skid surface coating, businesses can improve the efficiency and quality of their manufacturing process.

Hayden Corp. specializes in providing businesses with high-quality thermal spray coatings. We use the latest technology and equipment to ensure that our coatings meet the needs of our clients. Our experienced team is dedicated to providing the best possible service and customer satisfaction. To learn more about our thermal spray coating services, contact us today.

Questions?

Our staff is always available to answer your questions.

Categories