Thermal Spray Coating and Laser Cladding Solutions for Alabama

Our experienced technicians and specialists serving Alabama provide reliable solutions for demanding issues such as wear, corrosion, heat exposure, bonding failures, and surface degradation that impact critical components.

Built for Tough

Jobs Across Alabama

Industrial work in Alabama often pushes equipment to its limits. Heat, friction, and constant use can wear down parts faster than expected. Hayden Corporation provides thermal spray coating and laser cladding services that help components stand up to demanding conditions. Our solutions are designed to improve durability, reduce wear, and keep equipment performing reliably for industrial operations throughout Alabama.

Free Quote Request

Submit your information below

Alabama Quote

Thermal Spray Coating and Laser Cladding Services in Alabama

Industrial operations across Alabama rely on equipment that can hold up under constant stress, heat, and friction. To keep critical components performing reliably, Hayden Corporation provides thermal spray coating and laser cladding services that strengthen surfaces and extend service life. These processes are used to protect parts from wear, corrosion, and high temperatures common in demanding production environments.

Thermal spray coatings allow us to apply protective layers that improve surface durability without altering part dimensions. Laser cladding adds a dense, bonded metal layer that restores worn areas or reinforces components exposed to repeated use. Together, these services help Alabama manufacturers reduce downtime, improve consistency, and get more life out of their equipment.

Hayden Corporation works closely with customers to match each application with the right coating or cladding solution. Using proven methods and modern equipment, our team supports a wide range of industrial needs, including:

Thermal Spray Coating Services in Alabama

Founded in 1919, Hayden Corporation has built a long-standing reputation through decades of hands-on thermal spray coating experience. We work with industrial clients across Alabama, supporting a wide range of applications that require dependable surface protection. Because no two parts face the same operating conditions, we offer multiple coating options to match the specific demands of each project.

- HVOF Coating Services in Alabama: High Velocity Oxy-Fuel coatings provide strong adhesion, high hardness, and excellent wear resistance for components exposed to heavy use. These coatings are commonly used for hard chrome replacement, roll repair, cutting surfaces, and other areas that experience constant friction and abrasion.

- Flame Spray and Arc Spray Coatings in Alabama: Flame spray and arc spray methods apply molten material directly onto the surface to form a solid, protective layer. These coatings are frequently used to improve corrosion resistance, restore worn dimensions, add electrical conductivity, or provide thermal insulation for industrial components.

- Plasma Spray Coating: Solutions Plasma spray coatings use high temperature plasma to melt coating materials before application, creating dense and durable surfaces. This process allows for the use of materials with very high melting points, including ceramics, and is well suited for applications that require increased hardness and surface strength.

- Spray and Fuse Coating Options: Spray and fuse coatings are applied and then heat treated to create a strong bond with the base material. This process results in a durable, corrosion resistant surface that performs well in harsh operating environments where traditional coatings may not hold up

Laser Cladding Solutions in Alabama

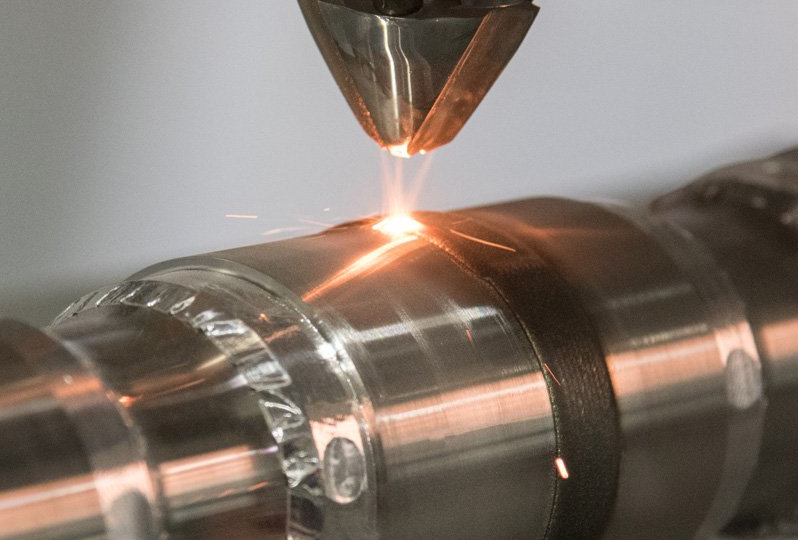

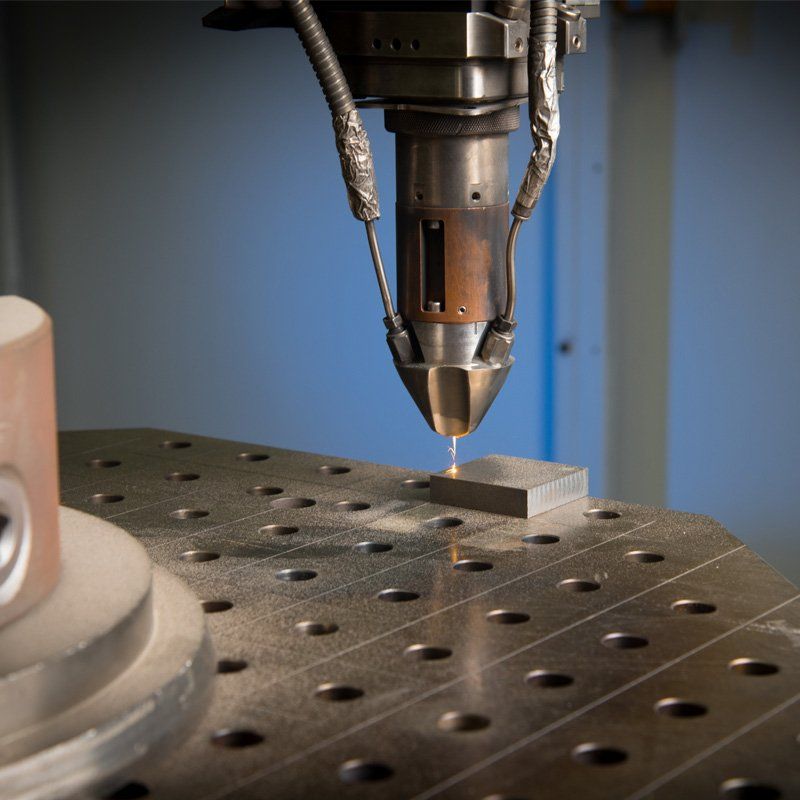

Hayden Corporation delivers advanced laser cladding services for manufacturers and repair operations across Alabama. Our automated laser cladding process supports both component restoration and original part production, allowing material to be applied with accuracy and consistency. The laser creates controlled deposits with clean edges, smooth finishes, and strong bonding to the base material, making it well suited for parts that require tight tolerances and dependable performance.

Advantages of Laser Cladding

Improved Wear Performance: Laser-applied alloys strengthen high-wear areas, helping components hold up longer under repeated use.

Added Corrosion Protection: The cladding process forms a solid protective layer that shields parts from corrosion, even in aggressive operating environments.

Better Heat Resistance:

Laser cladding enhances thermal performance, allowing components to maintain strength and reliability when exposed to elevated temperatures.

Alabamas Trusted Laser Cladding & Hardening Services

Laser Cladding

Our laser cladding team applies proven coating and welding knowledge using modern laser equipment to restore and protect worn components. This process adds material only where needed, helping Alabama manufacturers improve part life and reduce failure caused by wear or corrosion.

Precision 3D Cutting

Our laser cutting capabilities allow us to process metal parts with accuracy and consistency, handling materials up to ¼ inch thick. The system is paired with a five-axis CNC machine and a large 3m × 1.5m × 1.5m work envelope, giving us the flexibility to support detailed cuts and complex geometries for a wide range of industrial applications across Alabama.

Laser Hardening

Laser hardening strengthens heat-treatable metals by hardening only the surface areas exposed to wear. This method improves durability while maintaining the core strength of the part, making it a practical option for Alabama industries seeking consistent performance without distortion.

Thermal Spray Coating Services in Alabama

HVOF

HVOF coatings applied through high-velocity processes create tightly bonded, durable surfaces with excellent hardness and wear resistance. This method is well suited for components in Alabama that face heavy use, heat exposure, or demanding operating conditions.

Flame Spray & Arc-Wire

Flame spray and arc wire coating methods allow for flexible application, including work performed directly at customer sites. These proven processes offer a practical and cost-efficient option for large components and field-based projects across Alabama.

Plasma

Plasma spray coatings allow for a broad range of material options, from softer metals such as copper and iron to tougher carbides and ultra-hard ceramic materials. This flexibility makes plasma spraying a reliable choice for Alabama applications that require specialized surface performance.

Alabama Thermal Spray and Laser Cladding Services

Businesses across Alabama turn to Hayden Corporation for dependable thermal spray coating and laser cladding solutions. Whether you need surface protection for new components or restoration for worn parts, we provide a wide range of services designed to match your application and operating conditions. We work with customers throughout Alabama, including

Birmingham,

Huntsville,

Mobile,

Montgomery,

Tuscaloosa, and nearby areas. Contact our team today to request a free quote and discuss the right solution for your project.

Have a question or have a specific need? Contact our main office or send us a message online.