Laser Cladding & Laser Hardening

Offering precise control, coordinated by a single computer system.

High Quality Laser Cladding & Laser Hardening

Delivering the best engineered laser cladding solutions for your wear and corrosion problems.

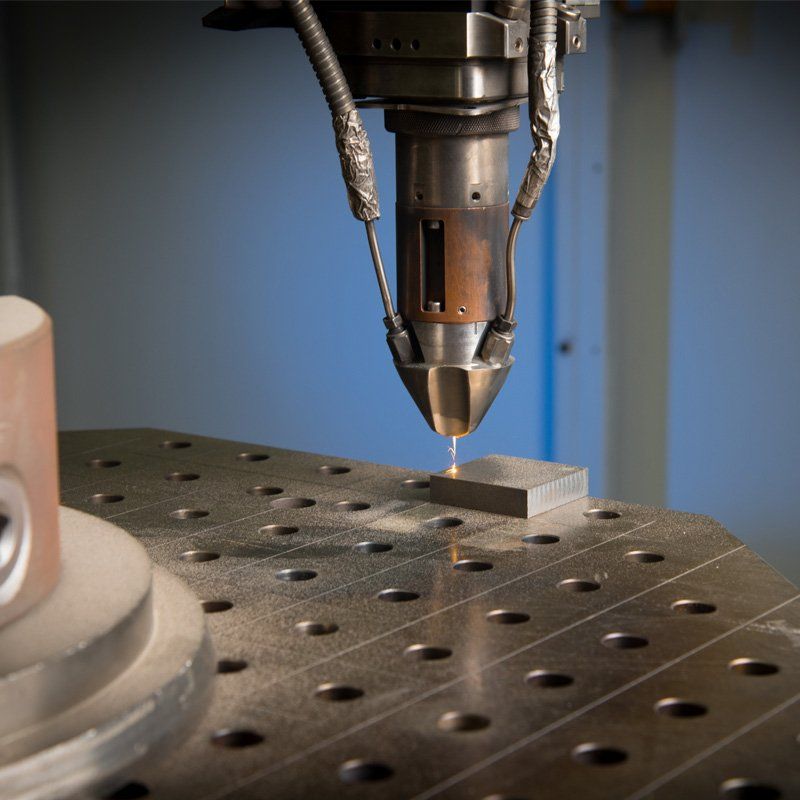

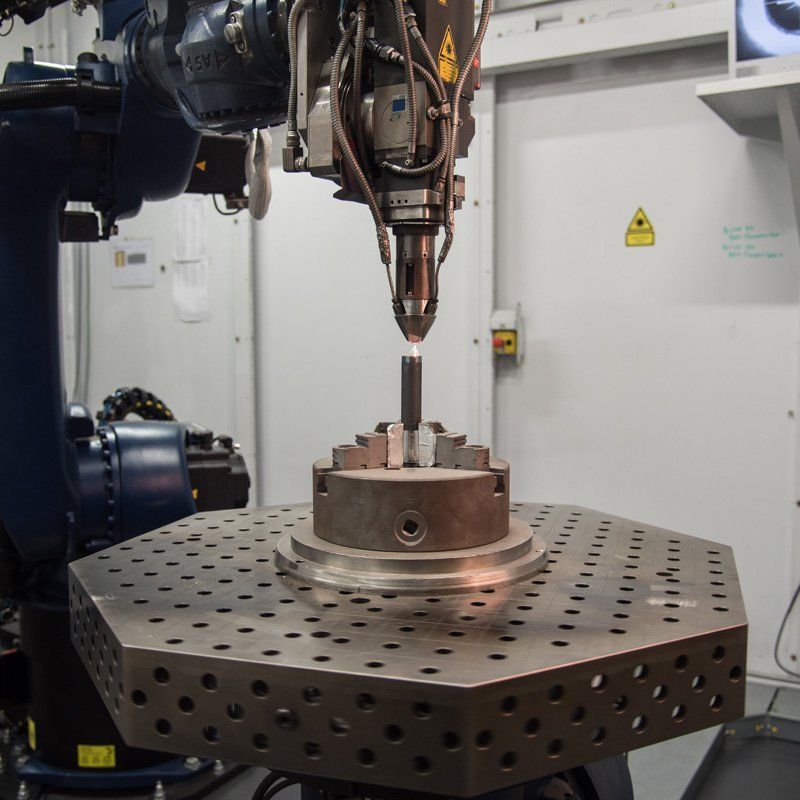

All laser cladding operations are fully automated, ensuring accurate and repeatable applications of the weld overlay. Laser cladding offers precise control, coordinated by a single controller.

Our laser cladding services department leverages our extensive history in the coating and welding industry with the highest-quality laser processing hardware available. We provide expert laser cladding services, delivering the best engineered laser cladding solution for your

wear and corrosion

problem.

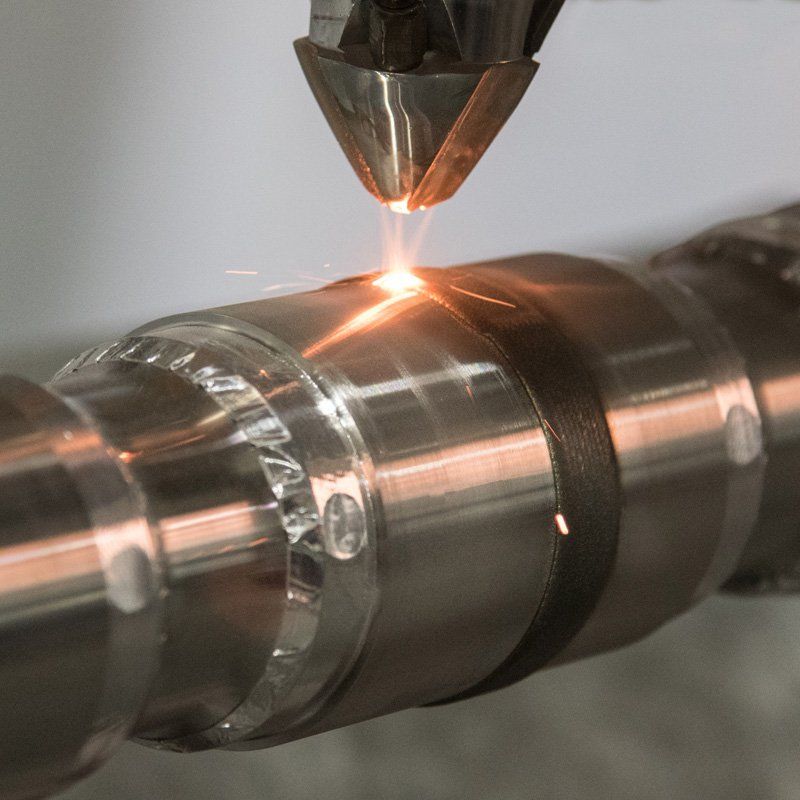

Wear Resistance

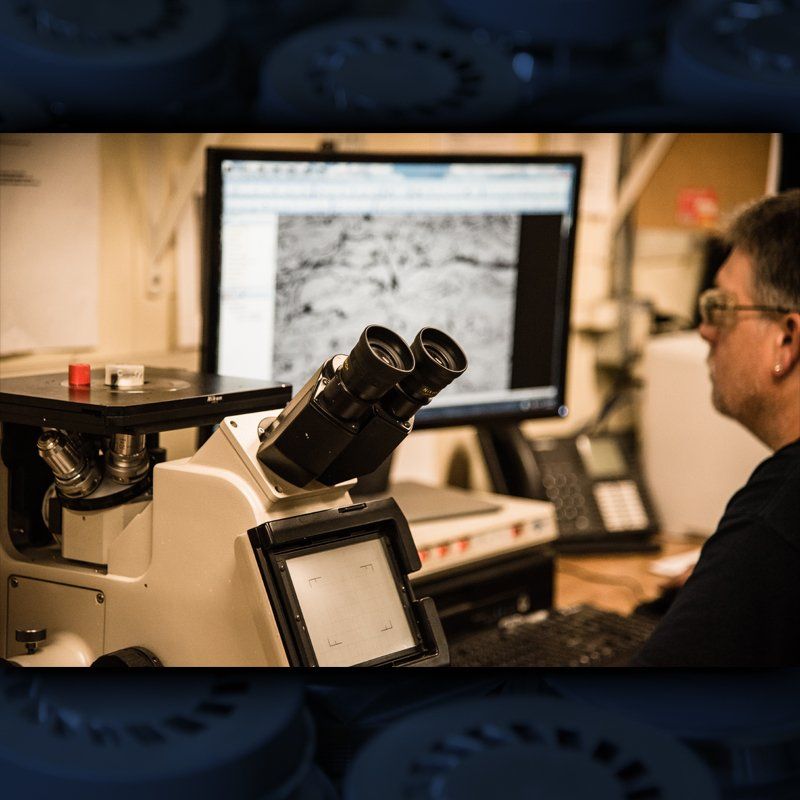

- Laser application of high-performance alloys (i.e. Stellite and Inconel), substantially increases surface toughness.

- Applying Spherical cast tungsten carbide can produce an almost indestructible armor against the most abusive wear environment.

Corrosion Resistance

- Unlike mechanically bonded coatings, laser-applied clad overlays are completely nonporous.

- Clad overlays provide an impenetrable barrier against harsh corrosives.

- Low heat-affected zone produced by this welding process ensures minimal change to the parent metallurgy and significantly reduces the risk of heat-related failures in operation.

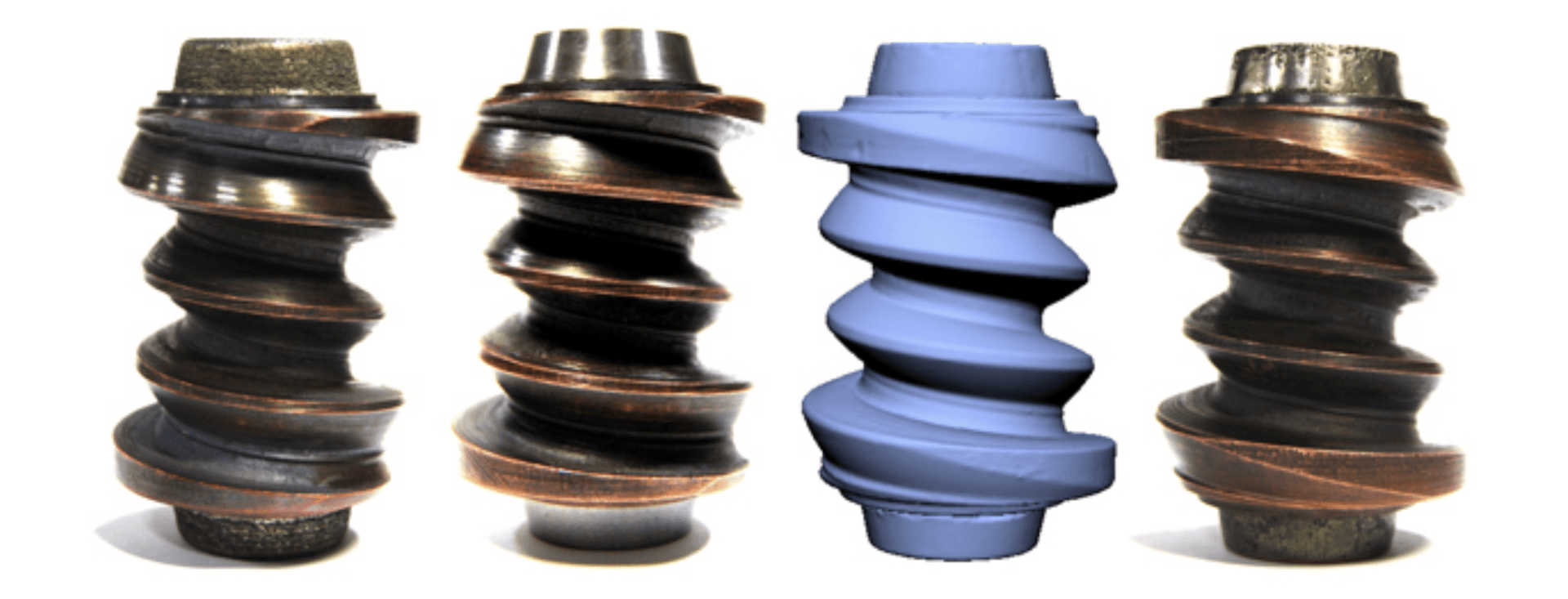

Other Laser Cladding Applications

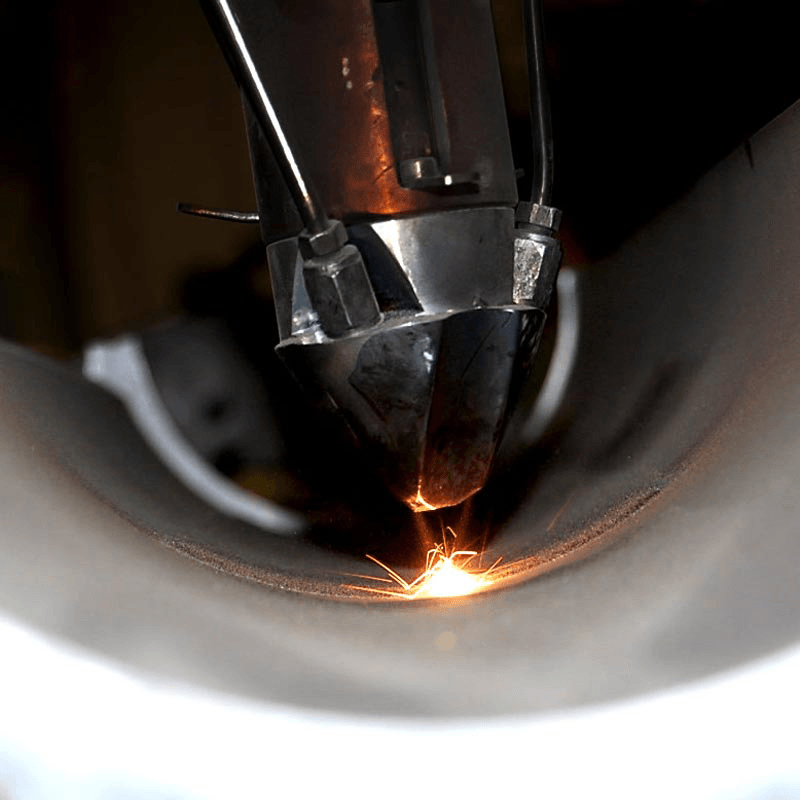

- Precise application of material makes dimensional restoration of service-worn components easy.

- In tandem with our in-house machining services, HLS can restore even the most worn component to like-new dimensions.

- Precise five-axis machining center is equally adept at cutting and has the advantage of a large 3m x 1.5m x 1.5m and 3D processing range to effect precise cuts on the most complex geometries.

Application Criteria

Laser clad overlays are excellent in a wide range of applications, but the higher cost of a welded overlay, when compared to a thermal spray solution, often demands that laser cladding services are primarily specified for only the most extreme applications.

Components being laser clad are exposed to higher temperatures than traditional thermal spray produces so care should be taken in applying overlays to low-tolerance parts at or near finished dimension. Our weld engineers can help you determine if our laser cladding services are right for your application. Call or email us to discuss your laser cladding project.

Laser Cladding & Laser Hardening Services

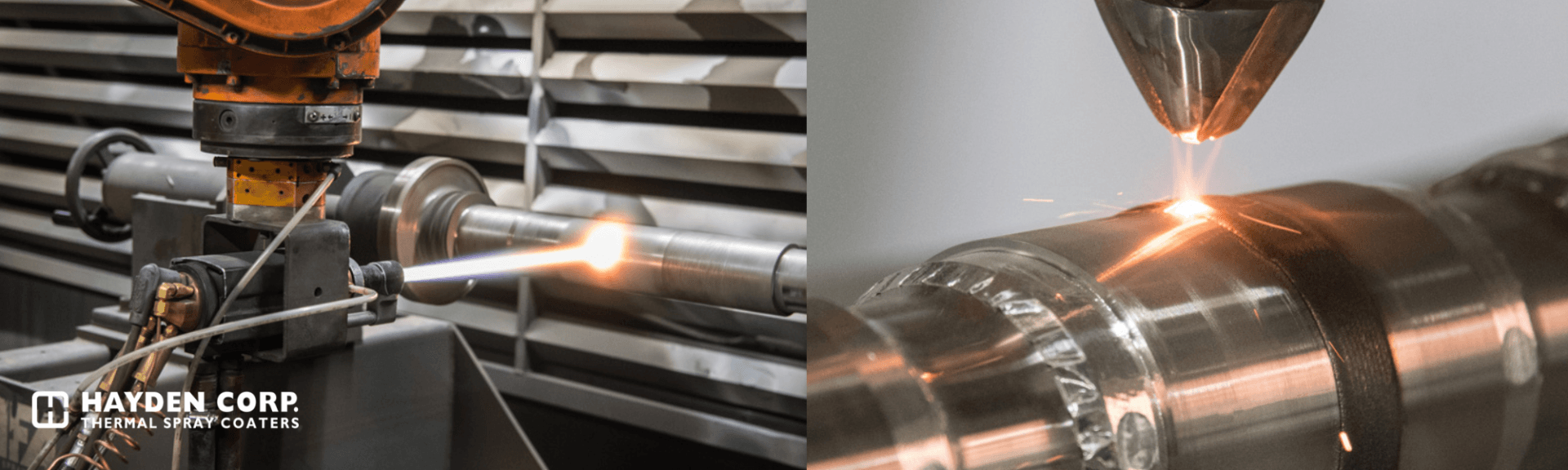

Laser Cladding

Our laser cladding services department leverages our extensive history in the coating and welding industry with the highest-quality laser processing hardware available. We provide expert laser cladding services, delivering the best-engineered laser cladding solution for your wear and corrosion problem.

Precision 3D Cutting

Precise control of an extremely high-quality laser beam allows fast, accurate cutting of metals up to a quarter of an inch thick. Coupled with a robust five-axis CNC machine tool and a large 3m x 1.5m x 1.5m work envelope, our laser system provides unparalleled cutting flexibility and accuracy.

Laser Hardening

Laser hardening is an alternative to furnace or flame hardening for heat treatable metals.

Laser Cladding & Laser Hardening Resources

View Our Gallery

Online Quote Request

Complete our online quote request form below. We will contact you within the same business day.

Laser Cladding Quote Request

Contact Hayden Corp.

Have a question or have a specific need? Contact our main office or send us a message online.