Breaking Down the Differences Between Laser Cladding and Thermal Spray

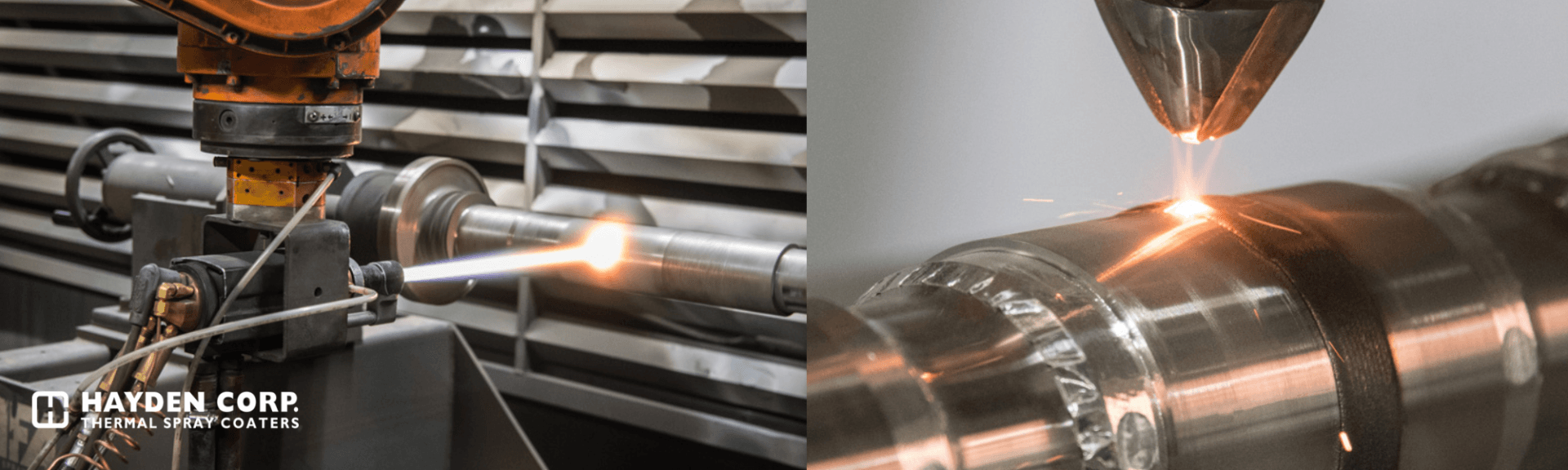

Laser cladding and thermal spray are similar yet distinct processes used to improve the surface properties of a substrate. Both methods involve depositing a protective or functional layer onto the substrate, but the two have several key differences. Let's take a closer look at laser cladding and thermal spray and explore the advantages and disadvantages of each method.

Laser Cladding

Laser cladding is a process that uses a laser beam to melt and deposit material onto the surface of a substrate. The laser energy also slightly melts the substrate, allowing the deposited material and the substrate to blend and allow. This melted material then cools and forms a metallurgically bonded layer on the substrate. Laser cladding can be used to deposit virtually any metallic material that can be welded.

Laser Cladding Advantages

Low Heat Input: laser cladding produces a very localized heat input, which minimizes the risk of distortion and thermal damage to the substrate.

Precise Deposition: laser cladding deposits a narrow, controlled weld bead, using a high-accuracy CNC machine tool, which allows for very precise deposition of material onto the substrate. This makes it ideal for repairing or adding features to delicate components.

Alloying and Cladding: laser cladding can be applied to create new alloys or cladding materials not possible with traditional methods. Multiple metallic materials can be injected and melted simultaneously.

Repairability: laser cladding can repair damaged or worn parts, restoring them to their original condition.

Laser Cladding Disadvantages

High Equipment Costs: laser cladding equipment is relatively expensive and requires a high level of operator training and experience.

Limited Material Selection: laser cladding is typically only possible with metals and alloys, and is not suitable for depositing ceramics or polymers.

Slow Process: laser cladding is a relatively slow process, making it unsuitable for high-volume production runs.

Thermal Spray

Thermal spray is a process in which a stream of molten or heated material is sprayed onto the surface of a substrate. The deposited material bonds mechanically to the roughened surface. This material then forms a coating on the substrate as it cools and solidifies. Thermal spray is a versatile technology with a wide range of applications. It is commonly used to improve the wear resistance, corrosion resistance, or electrical conductivity of surfaces.

Thermal Spray Advantages

High deposition rates: thermal spray can deposit material onto the substrate very quickly, making it suitable for high-volume production runs.

Protection from extreme conditions: thermal spray coatings can provide superior protection from extreme temperatures, chemicals, or abrasion.

Flexibility: Thermal spray can be applied to hard-to-reach places or irregularly shaped surfaces.

Wide range of materials: thermal spray can be used to deposit metals, alloys, ceramics, polymers, and even composite materials.

Extends the life of components: thermal spray coatings can significantly extend the life of components by protecting them from wear, corrosion, and other forms of damage.

Thermal Spray Disadvantages

High level of operator training and experience needed: thermal spray requires a high level of operator training and experience to produce consistent, high-quality results.

Risk of substrate damage: thermal spray can cause distortion and thermal damage to the substrate if not properly controlled.

Cost: thermal spray equipment is relatively expensive, and the process itself can be quite costly.

Now that you know a little bit more about laser cladding and thermal spray, you can decide which process is right for your application. If you need any help choosing the best coating method for your project, our team of experts at Hayden Corp would be happy to assist you. With over 100 years in business, we're experts in

thermal spray coating and laser cladding services. Contact us to learn more about our laser cladding and thermal spray services.

Questions?

Our staff is always available to answer your questions.

Categories