Blog

Arc spray has emerged as a reliable and versatile coating method, offering numerous advantages across various industries. With its enhanced coating durability, versatility in material selection, cost-effectiveness, surface restoration capabilities, improved performance, and environmental benefits, it has become a go-to choice for coating needs.

Ceramic coatings have long been known for their durability, wear resistance, and high-temperature properties. When it comes to wear resistance, these coatings are particularly effective in applications where materials require high hardness, protection from erosion, or chemical resistance. In this article, we'll provide an overview of some of the most common types of ceramic coatings used for wear resistance in thermal spraying.

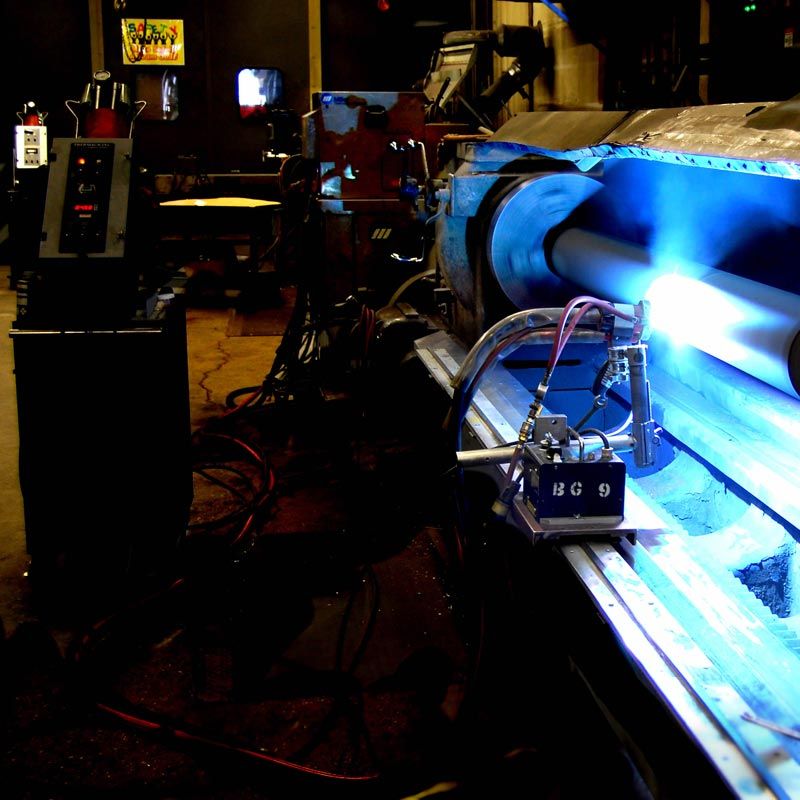

Thermal spray coatings offer several powerful benefits for the oil and gas exploration and processing industries. From increasing corrosion resistance to improving wear characteristics, these versatile coatings can help extend the life of critical components and protect against environmental factors that could otherwise cause expensive equipment damage.

Categories