EMI/RFI Shielding

EMI/RFI Shielding

Keeping sensitive data in and interference out, TEMPEST-qualified EMI/RFI shielding surfaces from Hayden provide a first line of defense in data security. HC302-E and HC303-E thermal sprayed shielding surfaces provide an economical way to maintain the light weight and flexibility of your existing non-conductive enclosures while providing the electrical integrity and security of steel.

Typical Applications:

- Computer and Display Housings

Active capture of emissions by grounding of the shield surface significantly reduces the likelihood of effective data piracy through the monitoring of stray emissions. - Navigational and Telemetry Equipment

Directional use of shielding surfaces can provide a barrier against ambient emissions that may detrimentally affect the accuracy of sensitive monitoring equipment. - Communications Transmission Environments

Protection of equipment and personnel in radio and television transmission facilities, microwave rebroadcast units, and similar high-ambient-RF environments.

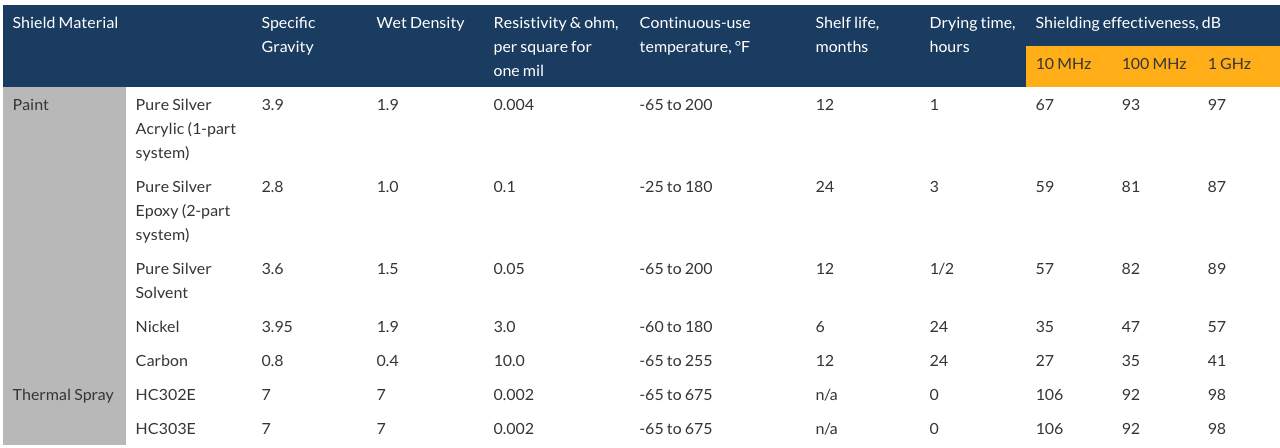

Developed to meet the needs of government and military contractors, our coatings provide shielding performance superior to metallic paint (see table below), and with far higher bond strength and resistance to flaking. Line-of-sight spray application allows for surfaces of nearly any geometry to be protected, and high deposition rates mean fast process time, rapid turnaround and affordable pricing.

Click Image to Enlarge

Data courtesy TAFA, Inc., Concord, NH.

The Federal Communications Commission specifies that most devices must remain passively susceptible to impingent interference.* Minimize risk and reduce compromising emissions with conductive surfaces from Hayden Corporation.

*See FCC 79-555/14686

Learn more about emi rfi shielding by Hayden Corp.

Questions?

Our staff is always available to answer your questions.

Categories