How to Decide When to use Plasma Spray or HVOF

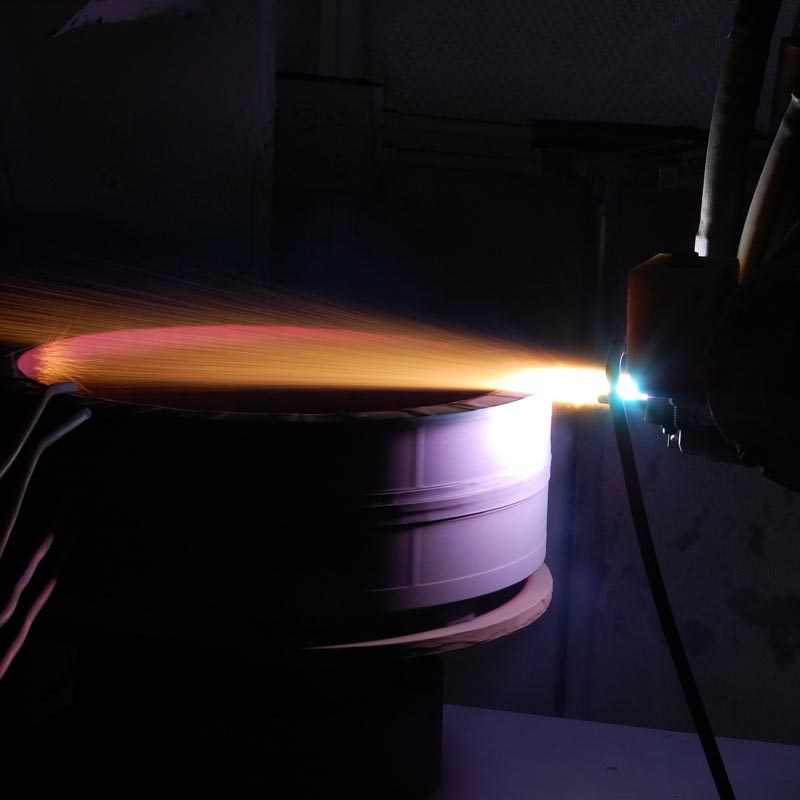

Secure your components with two of the most dependable protective coating technologies available: plasma spray and HVOF (high-velocity oxygen fuel). To ensure maximum performance, consider when to employ each process.

Use Plasma Spray for Parts That Require Superior Heat Resistance

Plasma Spray ensures your parts can handle extreme heat stress with its reliable and durable coatings. The higher temperature of the torch creates a dense coating of high melting point materials, resulting in more durable protection. This makes it ideal for parts with extremely high temperatures or that are subject to thermal cycling. Plasma spray also works well on components with complex geometries and large surface areas. Use plasma spray for parts that require superior heat resistance.

Use HVOF For Parts That Face Severe Wear (Abrasion Stress)

If your parts are facing severe abrasion stress, HVOF coating is the ideal solution for long-term protection. With its ability to provide a hard, wear-resistant surface that maintains dimensional accuracy and improves corrosion resistance, high-velocity oxygen fuel (HVOF) offers unbeatable quality assurance guarantees so you can rest easy knowing your parts will remain in top condition no matter what conditions they're exposed to.

If parts are expected to encounter high levels of abrasion and wear, HVOF is the way to go. For example, aerospace components must be able to withstand turbulent conditions, so HVOF delivers the hard-wearing strength that makes them suitable for use in such demanding environments. This coating also works well on parts with smaller surface areas, as it applies coatings with a higher bond strength that is more resistant to damage.

Choosing the Right Coating

Ultimately, both plasma spray and HVOF will protect your components from corrosion and wear, so it is up to you to decide which process would best suit your particular needs. By taking the time to understand the different applications and capabilities of each, you can ensure that you choose the right coating for maximum performance and longevity.

Both plasma spray and HVOF are excellent protective coatings, and it can be difficult to decide which one best suits your needs. Consider the expected environment and working conditions of the components, as well as their surface area size, geometry complexity, and temperature resistance requirements. With these factors in mind, you can make an informed decision about which coating to use for maximum protection.

Key Takeaways:

- Plasma spray is great for parts with extreme heat stress or complex geometries and large surface areas.

- HVOF is ideal for components exposed to extreme abrasion and wear.

- Consider the environment and working conditions of components when deciding which coating process to use.

- With the right information, you can choose the best protective coating for maximum protection and performance.

About Hayden Corp

Hayden Corp is a leading provider of thermal coatings and insulating solutions for the aerospace, defense, and industrial sectors. We are committed to providing high-quality products that meet our customers' stringent requirements. Our expertise in plasma spray and HVOF spray coating processes helps ensure that

Questions?

Our staff is always available to answer your questions.

Categories