Trusted Thermal Spray Coating and Laser Cladding in SC

Our experienced technicians and craftsmen support South Carolina industries by addressing surface wear caused by abrasion, heat exposure, corrosion, and other conditions that impact part performance and longevity.

Flexible Support for Demanding

Projects in South Carolina

Tough operating conditions place constant pressure on industrial equipment, making surface protection critical. Hayden Corporation provides thermal spray coating services and laser cladding services throughout South Carolina to help components hold up in challenging environments. These services are used to strengthen surfaces, reduce wear, and improve performance where reliability matters most.

Working with customers across South Carolina and the Southeast, Hayden Corporation supports applications that require durable, long-lasting solutions. Whether protecting new parts or restoring worn components, our thermal spray coating and laser cladding services are matched to the demands of each project.

Free Quote Request

Submit your information below

South Carolina Quote

Trusted Thermal Spray Coating

and Laser Cladding Experts Serving SC

Tough working conditions can take a toll on equipment and parts over time. To help components hold up, Hayden Corporation provides thermal spray coating and laser cladding services throughout South Carolina. Thermal spray coating helps protect surfaces from wear, heat, and corrosion, while laser cladding adds strength to high-use areas where extra durability is needed.

At Hayden Corp, we focus on matching the right thermal spray coating or laser cladding service to how each part is used. Our team works carefully with proven processes and modern equipment to deliver consistent, dependable results. By supporting industries across South Carolina, we help extend part life, reduce maintenance concerns, and keep equipment running as it should. Reach out to talk through your needs and see how our services can help.

Thermal Spray Coating Solutions

Serving South Carolina

Founded in 1919, Hayden Corporation brings decades of hands-on experience in thermal spray coating to manufacturers and facilities throughout South Carolina. Over the years, we’ve worked with a wide range of components and operating conditions, which has shown us that no two applications are the same. That’s why we offer multiple thermal spray coating options, allowing us to match the right process to the demands of each job.

HVOF Thermal Spray Coating: High-Velocity Oxy-Fuel thermal spray coating produces dense, well-bonded surfaces built to handle heavy wear. This process is often used for parts exposed to friction and repeated use, including roll surfaces, cutting edges, and applications that replace hard chrome finishes.

Flame and Arc Spray Coating: Flame spray and arc spray thermal spray coating methods apply molten material directly to the surface of a component, forming a protective layer with strong adhesion. These coatings are commonly used to improve corrosion resistance, reduce wear, add electrical conductivity, or provide thermal insulation in demanding environments.

Plasma Thermal Spray Coating: Plasma thermal spray coating uses high-energy heat to apply materials that require very high melting temperatures. This process is well suited for ceramic coatings and other hard materials where surface strength, heat resistance, and durability are critical.

Spray and Fuse Thermal Spray Coating: Spray and fuse thermal spray coating includes a fusing step that allows the coating material to bond more deeply with the base surface. The result is a dense, corrosion-resistant layer that performs well in tough service conditions where long-term durability matters.

Hayden Corporation provides thermal spray coating services for businesses across South Carolina, helping improve surface performance and extend the life of critical components. Contact us today to discuss which thermal spray coating option is the best fit for your application.

Laser Cladding Services in South Carolina

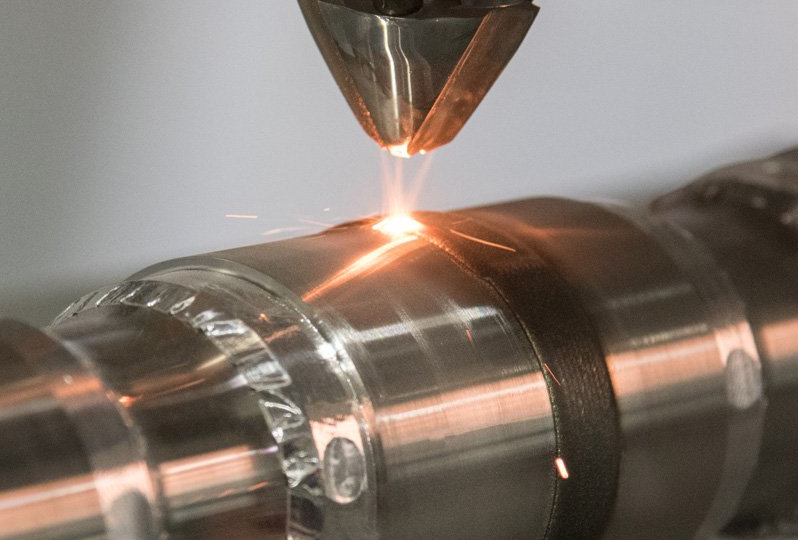

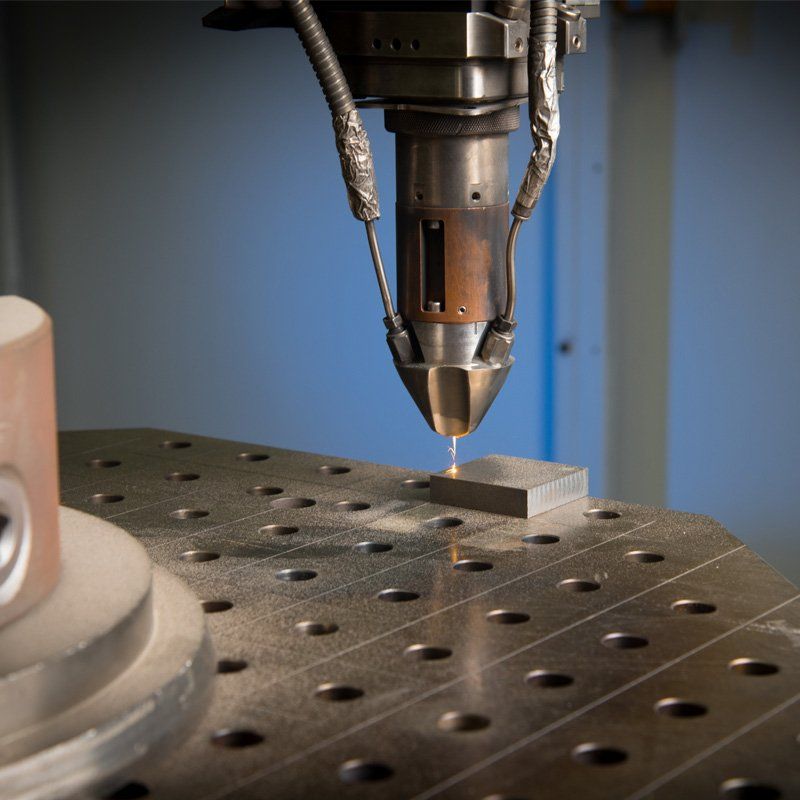

Hayden Corporation provides laser cladding services for businesses throughout South Carolina, supporting both part repair and new manufacturing needs. Laser cladding allows us to apply material with a high level of control, creating clean edges, smooth finishes, and strong bonding where added strength is needed. This process works well for components that must meet tight tolerances and perform reliably in demanding conditions.

Why Laser Cladding Is Used

Better Wear Protection

Laser cladding adds durable material to high-use areas, helping parts hold up longer under friction and repeated use.

Added Corrosion Resistance

The process forms a solid, protective layer that helps shield components from corrosion in harsh operating environments.

Improved Heat Performance

Laser-applied materials help components maintain strength and stability when exposed to high temperatures.

For South Carolina operations that need dependable surface reinforcement or part restoration, Hayden Corporation delivers

laser cladding services focused on durability and long-term performance. Contact our team to talk through your application and see if laser cladding is the right fit.

Laser Cladding and Hardening Services in South Carolina

Laser Cladding

Our laser cladding team has years of hands-on experience working with coatings and welded surfaces, supported by modern laser equipment. This allows us to apply laser cladding in a controlled, consistent way that helps address wear and corrosion issues for parts used across South Carolina.

Precision 3D Cutting

Using precise control of a high-powered laser, we’re able to cut metal cleanly and accurately up to ¼ inch thick. The system is paired with a five-axis CNC machine and a large 3m × 1.5m × 1.5m work area, giving us the flexibility to handle detailed cuts and complex shapes for a wide range of cutting needs throughout South Carolina.

Laser Hardening

Laser hardening provides a focused way to strengthen heat-treatable metals without the distortion often associated with furnace or flame hardening. This process allows specific areas of a part to be hardened while keeping the surrounding material intact, making it a practical option for many South Carolina applications.

Thermal Spray Coating Services in South Carolina

HVOF

HVOF thermal spray coating produces dense, tightly bonded surfaces that hold up well under heavy use. This process is often chosen in South Carolina for parts that require strong adhesion and long-term resistance to wear, heat, and demanding operating conditions.

Flame Spray & Arc-Wire

Flame spray and arc wire thermal spray coating methods can be applied directly at customer sites, making them a practical option for field work and large components. These proven processes offer a cost-effective way to add protection to equipment used in industrial settings across South Carolina.

Plasma

Plasma thermal spray coating supports a wide selection of materials, ranging from softer metals like copper and iron to harder carbides and ceramic materials that require very high heat to apply. This flexibility makes plasma spraying a strong option for South Carolina applications that need specific surface properties and dependable performance.

Trusted Thermal Spray Coating & Laser Cladding

Services in South Carolina

If you’re based in South Carolina and looking for reliable

thermal spray coating or laser cladding services, Hayden Corporation is ready to support your project. We offer a full range of surface solutions designed around how your equipment is used, whether you need added protection for new parts or restoration for worn components. Our team serves customers across South Carolina, including

Charleston,

Columbia,

Greenville,

Spartanburg,

Rock Hill, and surrounding areas.

Contact us today to request a free quote and discuss the right solution for your needs.

Have a question or have a specific need? Contact our main office or send us a message online.