Laser Cladding and Thermal Spray Coating Solutions in Vermont

In Vermont, our experienced craftsmen and technicians provide proven solutions for the toughest challenges, including abrasion, adhesion, corrosion, heat, and other wear issues affecting your parts.

Made for Demanding Projects in Vermont

When equipment is pushed to its limits in tough environments, every component must perform reliably. At Hayden Corporation, we make sure your parts are built to last. Through our Thermal Spray Coating and Laser Cladding services in Vermont, we deliver durable solutions that help your machinery handle the most demanding conditions with confidence.

Free Quote Request

Submit your information below

Vermont

Specialists in Thermal Spray Coating & Laser Cladding Across Vermont

Hayden Corp, a trusted name in thermal spray and laser cladding, proudly serves Vermont, including cities such as Burlington, Stowe, Rutland, and Brattleboro. Our thermal spray coatings and laser cladding services are designed to improve strength, durability, and resistance for a wide range of components. With a skilled team and advanced technology, Hayden Corp delivers dependable, high-quality results that meet the unique needs of every client.

We focus on tailoring our thermal spray coating and laser cladding services to each customer’s requirements. Using advanced equipment and proven methods, our team ensures consistent, long-lasting results.

Our services support a variety of industries and applications throughout Vermont, including:

Vermont Thermal Spray Coating Services

At Hayden Corporation, established in 1919, we bring over a century of knowledge and experience in thermal spray coating. This expertise extends throughout Vermont, where we’ve partnered with clients in many industries to tackle challenging applications. Since no two projects are the same, we provide a full range of thermal spray coating services tailored to each customer’s needs.

HVOF Coating – (High Velocity Oxygen Fuel)

The High-Velocity Oxy-Fuel (HVOF) process produces coatings with excellent hardness, bond strength, and wear resistance, making it ideal for components facing severe use. Typical applications include chrome replacement, roll surfacing, cutting edges, and other high-wear parts.

Flame Spray and Arc Spray in Vermont

Flame and arc spray coatings are applied by melting material and projecting it at high speed onto the component surface. This creates dense, durable layers with strong adhesion. These coatings are commonly used for corrosion resistance, wear protection, conductivity, and insulation.

Plasma Coating Services

Plasma spray coatings rely on ionized gas to melt and apply material to a surface, producing dense, tightly bonded finishes. This method is especially effective for high-melting-point materials such as ceramics, and it delivers harder, more durable results compared to many conventional processes.

Spray and Fuse Services in VT

Spray and fuse coatings undergo a final fusing stage that strengthens the bond between the coating and the substrate. This creates a durable, corrosion-resistant finish that outperforms many other thermal spray methods in demanding environments.

Laser Cladding Services in Vermont

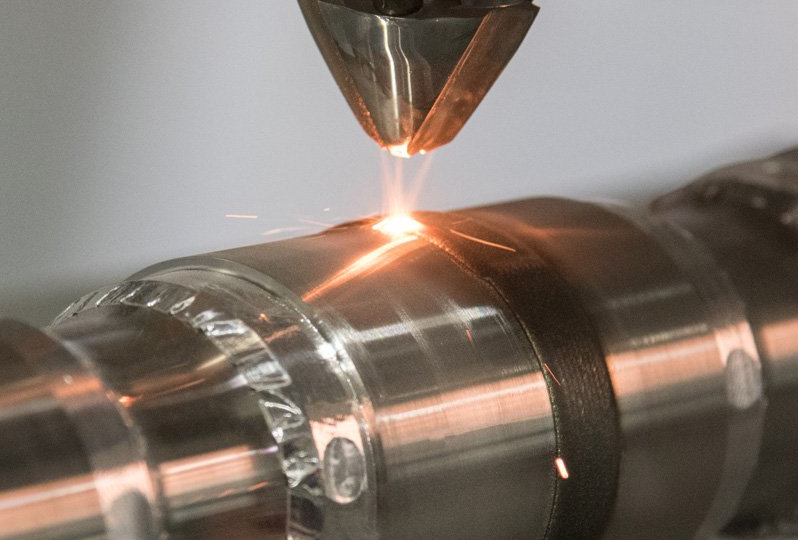

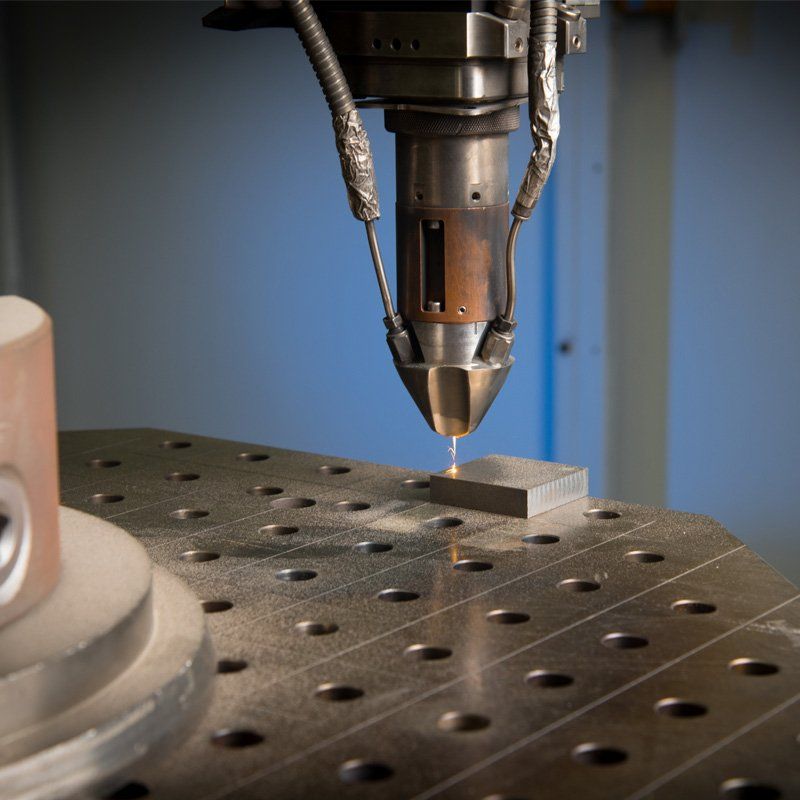

Laser cladding services from Hayden Corp provide fully automated laser deposition for both OEM production and component repair. Using advanced laser technology, we apply coatings with precise overlays, clean edges, smooth finishes, and strong metallurgical bonds. This process ensures we can meet strict tolerances and specifications for every project.

Benefits of Laser Cladding:

Wear Resistance:

Applying high-performance alloys with lasers improves durability and extends part life in demanding conditions.

Corrosion Resistance:

Laser cladding forms a dense, protective layer that shields components from rust and corrosive damage.

Thermal Stability:

Laser-applied coatings boost thermal performance, helping parts endure higher operating temperatures without loss of strength.

Laser Cladding & Hardening Services in Vermont

Laser Cladding

Our laser cladding services in Vermont bring together years of coating and welding experience with advanced laser processing equipment. We provide dependable solutions to combat wear and corrosion issues with accuracy and durability.

Precision 3D Cutting

Our advanced laser system in Vermont provides quick, accurate cutting for metals up to a quarter-inch thick. Combined with a five-axis CNC machine and a large 3m x 1.5m x 1.5m work area, it delivers reliable flexibility and high-quality results for a wide range of cutting needs.

Laser Hardening

Laser hardening provides an efficient and accurate option for strengthening heat-treatable metals, serving as a modern alternative to furnace or flame hardening.

Thermal Spray Coating Solutions in VT

HVOF

HVOF coatings deliver exceptional density, hardness, and bond strength, making them outperform many other application techniques.

Flame Spray & Arc-Wire

Flame spray and arc wire methods are portable, economical, and effective for on-site applications. These thermal spray coatings are especially well-suited for large projects.

Plasma

Plasma spray coatings can be applied with a broad range of materials, from softer metals such as copper and iron to durable carbides and very hard, high-melting-point ceramics.

Contact Us for Thermal Spray Coating

& Laser Cladding Services in Vermont

If you are looking for thermal spray coating or laser cladding services in Vermont, Hayden Corporation is here to help. We provide a full range of solutions customized to meet the unique needs of each client. Our services are available throughout Vermont, including

Burlington, VT,

South Burlington, VT,

Rutland, VT,

Barre, VT,

Montpelier, VT,

St. Albans, VT,

Winooski, VT,

Newport, VT,

Vergennes, VT,

Middlebury, VT,

Brattleboro, VT,

Bennington, VT, and surrounding areas. Contact us today to request a free quote.

Have a question or have a specific need? Contact our main office or send us a message online.