Expert Thermal Spray and Laser Cladding in Wisconsin

Our experienced team of technicians and craftsmen in Wisconsin provide effective solutions for challenges such as abrasion, adhesion, corrosion, heat, and other types of wear impacting your parts.

Made for Tough

Projects in Wisconsin

Your work is demanding, and your industry expects the best. Harsh conditions mean every machine and part needs to perform reliably. At Hayden Corporation, we ensure your components can handle even the toughest environments. Hayden Corporation Spray Coaters offers Thermal Spray Coating and Laser Cladding services throughout Wisconsin and the Midwest.

Free Quote Request

Submit your information below

Wisconsin Quote

Thermal Spray Coating and Laser Cladding Specialists Wisconsin

Challenging work environments demand machinery and components that perform at their best. That’s why we offer Thermal Spray Coating and Laser Cladding services throughout Wisconsin, designed to protect parts in the harshest conditions. Our Thermal Spray Coating process applies coatings that boost resistance to wear, corrosion, and heat. With Laser Cladding, we add a durable, wear-resistant layer that helps parts last longer and work more efficiently in demanding situations. If you’re looking to improve the durability and performance of your parts, Hayden Corporation can help you find the right solution.

Hayden Corp is dedicated to providing high-quality thermal spray coating and laser cladding services customized to each client. Our skilled and highly trained team uses advanced technology and equipment to deliver outstanding results. We serve a variety of industries, including

Thermal Spray Coating Services for Wisconsin

Founded in 1919, Hayden Corporation has decades of experience in thermal spray coating, earning a reputation for quality and precision. In Wisconsin, we’ve completed projects for clients across many industries. Each job comes with its own challenges, which is why we offer a range of thermal spray coating services to fit specific needs.

HVOF Coating Solutions

The High-Velocity Oxy-Fuel process creates coatings with outstanding bond strength, hardness, and wear resistance for parts in severe service. Common applications include hard chrome replacement, roll surfacing, cutting edges, and other high-wear surfaces.

Flame Spray and Arc Spray Services in Wisconsin

Flame and arc spray coatings are applied by melting the coating material and spraying it onto the surface, producing a dense, well-adhered finish. These are often used for corrosion protection, wear resistance, electrical conductivity, and thermal insulation.

Plasma Coating

Plasma spray coatings use ionized gas to melt and apply material, producing a dense and highly durable layer. This process can handle high-melting-point materials such as ceramics, delivering harder, longer-lasting surfaces than many other methods.

Spray and Fuse Coatings

Spray and fuse coatings undergo heat treatment after application to form a strong metallurgical bond with the base material. The result is a coating that is exceptionally tough and highly resistant to corrosion, perfect for demanding environments.

Laser Cladding Solutions in Wisconsin

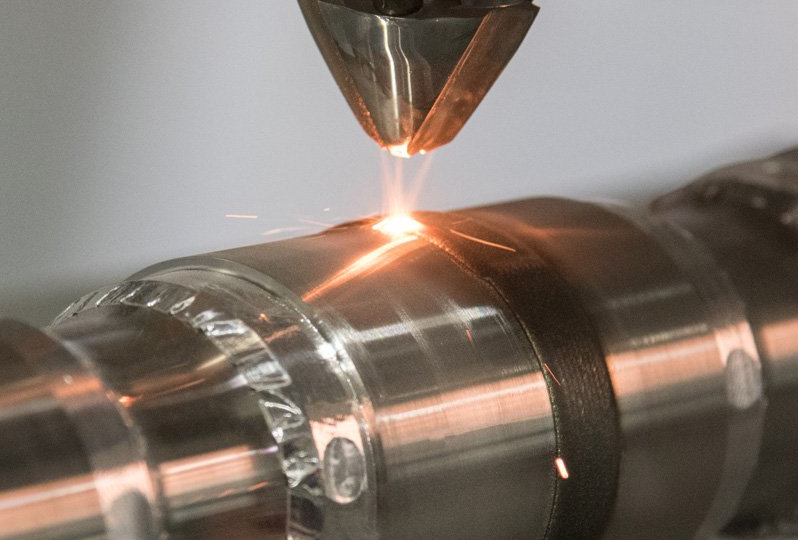

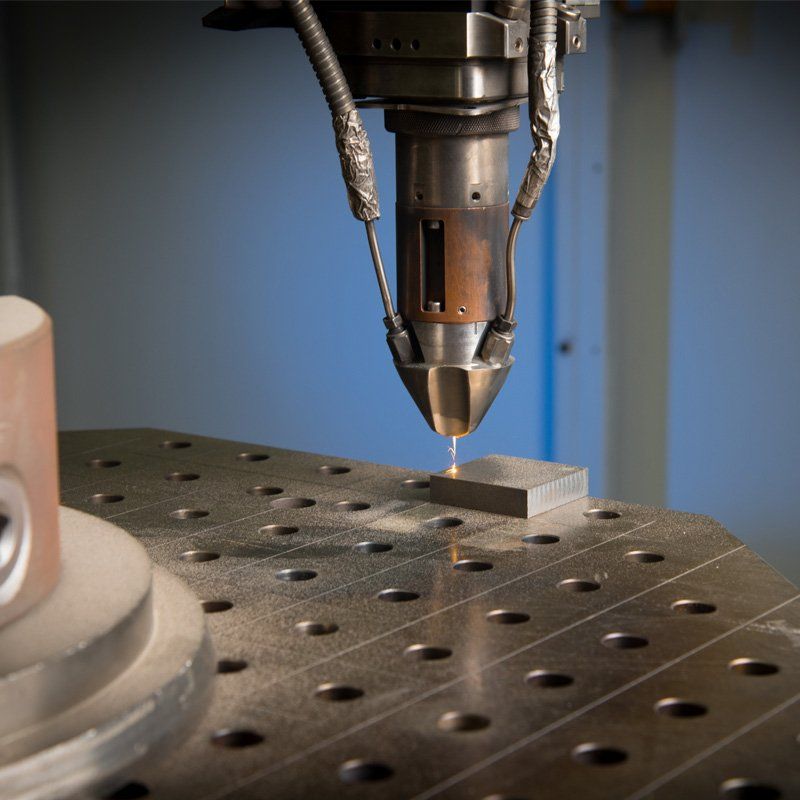

Hayden Corporation provides top-tier laser cladding services in Wisconsin, using fully automated laser deposition for both component repairs and OEM manufacturing. This process applies coatings with precision overlays, clean edge definition, smooth finishes, and strong metallurgical bonds—meeting the strictest tolerances and quality standards.

Benefits of Laser Cladding

Wear Resistance - Applying high-performance alloys with a laser significantly increases the wear resistance of components.

Corrosion Resistance - Laser cladding forms a dense, protective barrier against corrosion, making it well-suited for harsh operating environments.

Thermal Stability - Laser-applied coatings enhance thermal stability, ensuring reliable performance in high-temperature applications.

Laser Cladding and Hardening Services in Wisconsin

Laser Cladding

Our laser cladding team brings years of coating and welding experience together with advanced laser equipment. We provide effective solutions to combat wear and corrosion for industries throughout Wisconsin.

Precision 3D Cutting

With careful control of a high-quality laser beam, we can cut metals up to a quarter inch thick quickly and accurately. Combined with a five-axis CNC machine and a large 3m x 1.5m x 1.5m work area, our laser system offers accuracy and flexibility for many cutting needs in Wisconsin.

Laser Hardening

Laser hardening is an efficient alternative to furnace or flame hardening for heat-treatable metals in Wisconsin.

Thermal Spray Coating in Wisconsin

HVOF

HVOF coatings deliver high density, hardness, and bond strength, often performing better than many other application methods in Wisconsin.

Flame Spray & Arc-Wire

Flame spray and arc wire coatings are portable and can be applied on-site at customer locations. Reliable and cost-effective, these thermal spray methods are well-suited for large-scale projects in Wisconsin.

Plasma

Plasma spray coatings can use many different materials, from softer metals like copper and iron to strong carbides and very hard, high-melting-point ceramics, for applications in Wisconsin.

Request Thermal Spray Coating and Laser Cladding

Services in Wisconsin

If you are in Wisconsin and looking for thermal spray or laser cladding services, Hayden Corporation is here to assist. We provide a complete range of thermal spray coating and laser cladding solutions to fit your specific needs. Our services are available across Wisconsin, including

Milwaukee,

Madison,

Green Bay,

Kenosha,

Racine, and nearby areas.

Contact us today for a free quote.

Have a question or have a specific need? Contact our main office or send us a message online.